Why Roller Spacing Is Also Key to Veneer Drying?

Why Roller Spacing Is Also a Key to Veneer Drying?

In the intricate world of wood processing, the efficiency of a veneer production line hinges on the performance of its heart: the roller veneer dryer. While factors like temperature control and airflow often dominate discussions, one fundamental yet frequently overlooked design element plays a pivotal role in determining final product quality, operational stability, and energy efficiency—the precise spacing between the dryer's rollers. Shine Machinery, a leader in intelligent drying solutions, has long championed the engineering principle that optimal roller spacing is not a mere detail, but the cornerstone of high-performance drying.

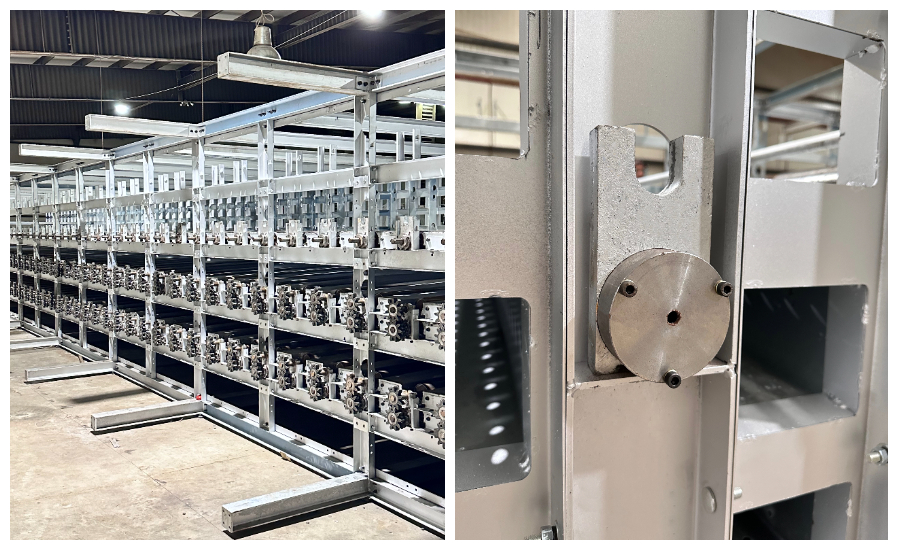

The design of a roller veneer dryer is a complex exercise in balancing multiple physical forces. The rollers serve a dual purpose: they must transport delicate, often wet, veneer sheets through the drying chamber without causing damage, while simultaneously facilitating the most efficient possible heat transfer from the air to the wood. The gap between these rollers—the spacing—becomes a critical variable that directly influences several key outcomes.

Firstly, and most critically, spacing dictates the prevention of deformation and breakage. As veneer loses moisture, it shrinks and internal stresses develop. Without continuous and uniform support, these stresses cause the sheet to sag between rollers, leading to permanent warping, cracking, or the development of wavy edges. This renders the veneer unusable for high-value applications like furniture faces, directly impacting profitability. Secondly, spacing is paramount for ensuring uniform drying. The gaps between rollers are the primary channels for hot air to circulate and penetrate the veneer sheets. Spacing that is too narrow restricts airflow, creating stagnant zones that result in uneven moisture content—some areas become brittle while others remain damp. Conversely, excessively wide spacing does little to mitigate the risk of sagging. Finally, proper spacing ensures smooth and stable operation. It minimizes friction, reduces the load on the drive system, and prevents veneer from slipping or tracking off course, which is essential for maintaining a continuous production flow and reducing unplanned downtime.

For mid-capacity production lines, a spacing of 330mm has emerged as an industry benchmark for processing common hardwood and softwood veneers ranging from 1mm to 6mm in thickness. This measurement is not arbitrary; it is the result of extensive material science and practical application. For veneer in this thickness range, 330mm provides the ideal stiffness-to-weight support ratio. It offers just enough contact points to prevent the sheets from sagging beyond their elastic limit, allowing them to spring back to a flat state after drying. Furthermore, this distance creates the perfect aerodynamic channel for heat exchange, allowing high-velocity air to scrub moisture from both sides of the sheet efficiently. This balance is why a four-deck dryer, a workhorse configuration for balanced output and footprint, frequently employs this spacing to achieve high throughput without compromising quality.

Shine Machinery integrates this deep understanding of mechanical engineering and thermodynamics into every dryer they design. For them, the choice of roller spacing is a calculated decision tailored to the client's specific production goals. Rather than applying a one-size-fits-all approach, their engineers model the interaction between veneer species, thickness, and dryer dynamics to specify a spacing that will yield the highest grade-out rate. A dryer designed with precision spacing requires less energy to achieve the desired moisture content, as the improved airflow translates to more effective heat transfer. This leads to significant reductions in fuel consumption, a major operational cost, and a lower carbon footprint for the production facility.

The expertise of Shine Machinery extends beyond mere construction. They recognize that a well-designed dryer is an intelligent system. By optimizing a fundamental parameter like roller spacing, they ensure that the entire machine—from the infeed to the heat recovery unit—operates in harmony. This results in a more reliable asset that produces higher-quality veneer with fewer rejects, less maintenance, and greater energy efficiency. In an industry where margins are tight and quality demands are ever-increasing, this attention to foundational engineering details is what separates adequate equipment from exceptional performance.

In conclusion, the question of roller spacing transcends a simple technical specification. It is a fundamental design philosophy that prioritizes precision, quality, and efficiency. As manufacturers seek to upgrade their operations, partnering with experts like Shine Machinery, who base their designs on these core principles, is the most strategic decision to ensure a competitive edge in the global market.