Smarter Drying for Stronger Wood

The Heat That Builds Better Wood

When we first built our wood processing plant dryer, we didn’t just chase numbers. We chased perfection.

Every piece of wood tells a story — if you dry it wrong, it warps, cracks, and loses its soul. But when you dry wood right, it transforms into a strong, stable masterpiece.

At Shine Machinery, we live and breathe this process. Every screw, fan, and sensor in our dryers exists to help you reduce moisture content without burning extra energy. It’s science, art, and a touch of madness — in the best way.

Why Drying Defines Quality

You can’t fake a good drying process. The heart of durable wood lies in how we remove water.

1. The Battle Against Moisture

Moisture sneaks into every fiber. If we skip proper control, it causes deformation later.

That’s why we focus on controlling both temperature, humidity and initial moisture levels from the start.

A log fresh from the saw can hold over 100% moisture (yes, more water than wood). The mission is simple — bring that number down without damaging fibers.

2. Air Drying vs. Kiln Drying

Many plants begin with air drying, which is cheap but slow. It depends on the weather, and trust me, rain doesn’t care about your schedule.

That’s where kiln drying comes in — controlled, faster, and precise. It lets us hit perfect drying conditions year-round.

We usually start with air drying, then shift to kiln or belt systems for final precision. This two-step process keeps energy costs reasonable while delivering high-quality boards.

The Science of Uniform Drying

We’ve learned one golden rule: never rush nature, just guide it smarter.

Controlling the Drying Process

Inside our drying system, hot air moves in calculated patterns. Sensors constantly track temperature, humidity and adjust flow speed.

This ensures wood dries uniformly dry — every section, every layer.

Uneven drying leads to cracks. Even drying builds consistency. We prefer the latter every single time.

Adjusting for Different Woods

Oak, pine, birch — each species behaves differently. We tweak the drying time, airflow, and heat curves to suit each type.

Think of it like cooking. The secret isn’t just temperature; it’s timing.

Energy Efficiency: Smarter Heat, Lower Bills

Energy prices hurt, and we feel that too. So we designed our dryers to be energy efficient from day one.

1. Reusing Heat

Our belt dryers recycle exhaust air after filtering and reheating. That saves up to 25% on energy consumption.

2. Targeted Heat Zones

Why heat empty air? Our system pushes energy only where wood sits. Intelligent airflow sensors guide fans to adjust in real time.

3. Long-Term Cost Benefits

Sure, the system costs more upfront. But over time, lower bills and maintenance make it pay for itself.

We’ve seen clients cut annual costs by thousands. And they still thank us years later.

The Art of Reducing Moisture Content

Drying wood is not just about removing water; it’s about reducing moisture content to the sweet zone.

Measuring Moisture Accurately

We monitor each batch. Sensors check both surface and core levels.

If one side dries too fast, we can slow the airflow or lower the temperature. This avoids tension that causes cracks.

Our final moisture level usually hits between 6–12%, depending on the final product use.

That’s the balance point for stability and performance.

Drying Conditions That Matter Most

We never leave drying to chance. We monitor three key parameters at all times:

1. Temperature — keeps the fibers relaxed while water escapes.

2. Humidity — controls how fast water leaves without stress.

3. Air speed — balances drying pressure inside and out.

When these three align, wood stays smooth, straight, and strong.

Even humidity drops need precision — a sudden drop causes internal cracking. We call that the “thermal trap,” and it’s every plant’s nightmare.

Improving Efficiency Beyond Hardware

Hardware helps, but smart operation makes the magic.

1. Optimize Drying Time

We log every batch. Then we adjust based on results — fewer trials, more data.

Sometimes, cutting just 30 minutes saves significant energy without affecting drying results.

2. Maintenance Routine

Clean filters weekly. Check belts monthly. Replace sensors yearly.

A healthy machine stays efficient for decades.

3. Training the Team

We train operators to “listen” to the wood — subtle color changes and scent shifts often signal readiness better than sensors. That human touch keeps our drying solutions reliable.

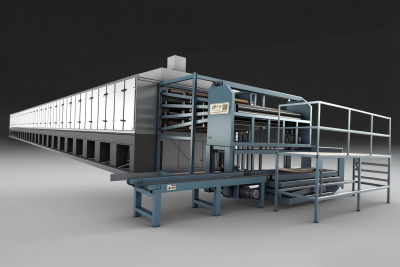

Belt Dryers: Quiet Heroes of Modern Drying

When we designed our belt dryers, we didn’t just copy old designs. We reinvented airflow. The continuous belt moves wood gently through multiple heat zones. Each zone has specific temperature and humidity levels, matching the wood’s internal state.

This precision gives incredibly consistent drying. You could measure moisture across ten boards — all within a 0.5% difference. That’s how we keep products uniformly dry without overcooking any fiber.

When the Veneer Drying Machine Joins the Process

While most people focus on bulk timber, veneer drying is another beast. Shine Veneer Drying Machine specializes in thin layers that require extremely even airflow and gentle heat. We align it with the main wood processing plant dryer for a seamless workflow. From thin veneers to thick planks, every piece passes through our drying system tuned for excellence. It’s like having a full orchestra — each instrument tuned, each note perfect.

Long-Term Reliability Built into Every Dryer

Drying systems face extreme conditions: heat, humidity, vibration, and dust. We engineer ours for long-term reliability — reinforced frames, corrosion-resistant surfaces, and smart diagnostics that catch issues early. We even use temperature-resistant bearings that handle years of daily use without noise or slowdown. In short, we don’t build machines that just work. We build partners that last.

Unexpected Truths About Drying

Let’s get honest for a second. Drying wood isn’t always glamorous. It’s hot, noisy, and sometimes unpredictable.

But there’s a strange beauty in it. Watching raw, wet boards become sleek, dry wood ready for transformation feels like alchemy. Our team often jokes that we’re more like “wood whisperers” than engineers. Because when you spend years watching moisture turn to vapor, you start to understand patience — and the quiet power of precision.

Final Thoughts: Drying for the Future

As we look forward, we see drying evolving with technology.

AI-controlled drying systems that predict wood behavior, self-cleaning filters that save time, and even solar-assisted heating to push energy-efficient production further. But no matter how smart the tech becomes, one truth stays:

Drying isn’t just about heat. It’s about care.

We don’t just dry wood.

We build strength into it.