Veneer Dryer with Biomass Burner

Shine’s 4 Decks Roller Veneer Dryer: The Ultimate Solution for Customizable Wood Veneer Drying

In the competitive wood processing industry, maximizing productivity while minimizing operational costs is key. Meet Shine Machinery’s 4 decks Roller Veneer Dryer—our newly optimized model designed to address diverse client needs, from small-scale workshops to large industrial production lines. Whether you’re drying birch, oak, or rubberwood, Shine innovative veneer drying machine combines cutting-edge technology with user-centric design to deliver unmatched performance.

4 Deck Veneer Dryer Structure: Boost Productivity Without Compromising Quality

The 4 decks configuration of Shine’s roller veneer dryer is a game-changer. By stacking four drying layers vertically, it significantly increases throughput without expanding floor space. Clients now have the flexibility to choose between semi-automatic or fully automatic veneers collection at the discharge end, adapting to their specific workflow demands. For those prioritizing full automation, the fully automatic system ensures seamless veneers feeding and collection, reducing labor costs and minimizing human error.

Biomass Drying: Sustainable, Cost-Effective Heating

At Shine Machinery, we understand that operational costs directly impact profitability. That’s why 70% of our clients opt for our biomass burner as the heat source for their 4 decks roller veneer dryer. Designed to burn waste wood chips (a byproduct of rotary cutting), this system transforms scrap into energy—slash fuel expenses by up to 40% compared to traditional fossil fuels. Whether you’re processing thin or thick veneers, the biomass burner maintains stable temperatures (140–180°C) required for optimal drying, ensuring consistent quality while supporting eco-friendly practices. For clients integrated into plywood production lines, we also offer customizable options using thermal oil or steam heat sources, ensuring seamless compatibility with existing systems.

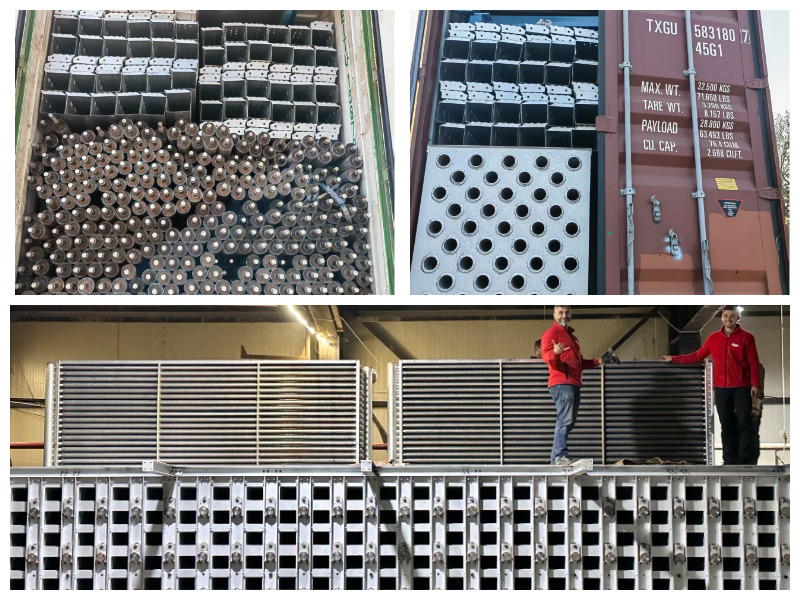

Advanced Heat Exchange Technology: Uniform Drying, Every Time

What sets Shine’s veneer drying machine apart is its proprietary heat exchange system. Each section of the dryer features independently developed, high-temperature-resistant heat exchangers, carefully engineered to distribute heat evenly across all drying zones—especially critical near the biomass burner where temperatures are highest. Paired with our intelligent hot-air circulation system, hot air flows strategically over every veneer sheet, eliminating cold spots and ensuring uniform moisture removal. This precision prevents edge cracking and guarantees flat, high-quality veneers with consistent moisture content—key to meeting the strict standards of global wood markets.

Versatile Sizing & Custom Solutions for Global Clients

Shine ’s 4-layer roller veneer dryers are built to adapt. We offer multiple working width options (3m, 3.5m, 3.75m, 3.9m, 4.5m, 5m, 6m) to match your veneer size requirements, whether you’re drying narrow strips for furniture or wider planks for construction. With a proven daily output of up to 240m³, this model scales effortlessly to match your production goals. Beyond sizing, we specialize in customized designs—tailoring dimensions, heat source configurations, and discharge systems to your factory layout, raw material specifications, and operational preferences. No two drying lines are the same because no two clients are the same.

Proven Performance Across Global Markets

From European furniture manufacturers to African plywood mills and Asian woodworking workshops, Shine’s 4-layer roller veneer dryers have earned a reputation for reliability. Clients consistently praise their ability to dry diverse wood species—including birch, oak, beech, eucalyptus, pine, rubberwood, and acacia—without compromising on flatness or moisture uniformity. This versatility, combined with our focus on energy efficiency and customization, has solidified Shine Machinery as a trusted partner in the global wood processing industry.

Why Choose Shine Machinery’s 4-Layer Roller Veneer Dryer?

Multi-layer efficiency: 4 layers maximize output in compact spaces.

Biomass-powered savings: Burn waste wood for lower fuel costs.

Uniform drying: Proprietary heat exchangers and hot-air circulation ensure consistent quality.

Custom-fit solutions: Tailored to your factory, materials, and goals.

Ready to elevate your wood drying process? Contact Shine Machinery today to learn how our 4-layer roller veneer dryer can transform your production—delivering higher yields, lower costs, and superior veneer quality, all under the Shine brand of excellence.

Shine Machinery: Drying Innovation, Global Trust.