News Center

Shine’s Director Leng Conducts On-Site Inspection of Birch Origins, Forging Strategic Partnerships to Secure High-Quality Raw MaterialsOn September 25, Mr. Leng, Director of Shine Machinery, embarked on a field trip to a key birch-growing region, engaging in in-depth face-to-face discussions with…

2025/09/26 10:26

In the world of wood veneer production, the 4-deck roller veneer dryer has emerged as a quiet yet dominant force—second only to its 2-deck counterpart in sales but outshining it in popularity for key practical reasons. At Shine Machinery, we’ve observed this trend firsthand, especially with clients…

2025/09/25 17:01

Project Background: Meeting Local Demand for Quality VeneersCôte d'Ivoire, a major producer of tropical hardwoods, has long faced challenges in drying veneers efficiently while maintaining strict quality standards. Traditional drying methods often struggled with inconsistent moisture levels, high…

2025/09/24 10:23

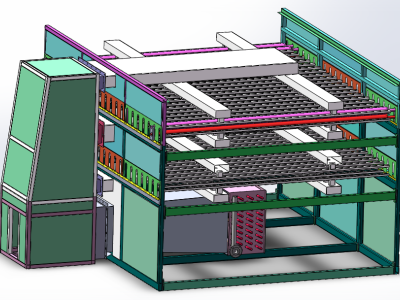

On September 21, a client from Sichuan Province visited Shine Machinery’s production facility for an in-depth inspection of its veneer dryer equipment. This visit marked a critical step in the client’s plan to invest in a local veneer production line targeting exports to Europe and the U.S.—a…

2025/09/22 11:13

Pine veneers, widely used in furniture manufacturing and interior decoration, require careful handling during drying to preserve quality. Due to their unique properties—high resin content, coarse fibers, and susceptibility to cracking—special precautions are essential when using veneer dryers.…

2025/09/19 13:49

Shine Roller Veneer Dryer Install ProcessAs a long, large-scale piece of equipment, the installation of Shine’s roller veneer dryer requires adherence to a precise sequence and method. Below is the detailed installation process to ensure optimal performance and safety.1. Mark Foundation LinesBegin…

2025/09/17 14:18

Drying plywood can feel like waiting for water to boil. Slow, frustrating, and costly. We know because we live in this world every day.At Shine Machinery, we build Veneer Dryer Machines and obsess over how to dry plywood fast without hurting quality. In this guide, we’ll share what we’ve learned.…

2025/09/16 11:06

In a significant leap forward for the wood processing industry, Shine Machinery—renowned for its innovative drying solutions—has unveiled its latest generation of axial fans, specifically engineered for high-capacity wood veneer dryers. This breakthrough addresses critical challenges in large-scale…

2025/09/15 15:20

Plywood, a composite material made by gluing multiple layers of veneer, is renowned for its strength, stability, and versatility. Its production involves a meticulous, science-driven process designed to optimize structural integrity and performance. Below is a detailed breakdown of the key steps in…

2025/09/11 10:48

Drying veneer is not just a step in veneer production. It is the heartbeat of quality veneer manufacturing.If we rush it, the veneer sheets crack or warp. If we take too long, we waste energy and lose profit. The question every producer asks is simple: How long does it take, and what is the process…

2025/09/09 11:21

On September 5, Mr. Tang, Ambassador of the Chinese Embassy in Latvia, led a delegation to inspect the newly operational site of Shine Veneer Dryer in Latvia—a landmark visit that highlights the growing global recognition of Chinese innovation in the European wood processing industry. During the…

2025/09/08 10:54

In the world of premium woodworking materials, beech plywood has emerged as a standout choice, celebrated for its exceptional properties and wide-ranging applications. Derived from beech—a hardwood revered globally for its superior physical and mechanical performance—beech plywood combines natural…

2025/09/05 11:28