The difference between Centrifugal Fans and Axial Fan

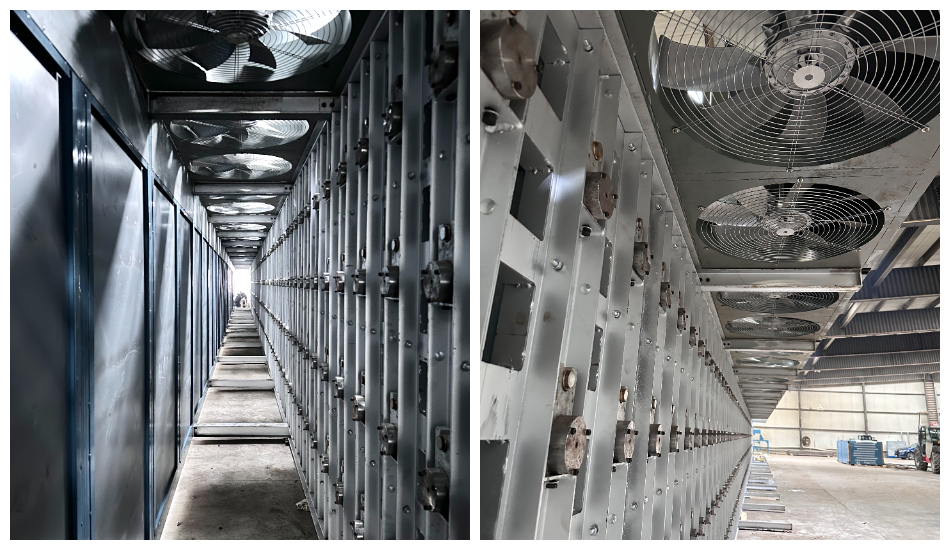

In a significant leap forward for the wood processing industry, Shine Machinery—renowned for its innovative drying solutions—has unveiled its latest generation of axial fans, specifically engineered for high-capacity wood veneer dryers. This breakthrough addresses critical challenges in large-scale veneer production, offering unprecedented airflow efficiency, uniform drying performance, and energy savings.

The Challenge: Scaling Drying for Large-Volume Veneer Production

As global demand for plywood and wood-based panels grows, manufacturers face mounting pressure to scale production while maintaining strict quality standards. Central to this challenge is the need for reliable, high-performance ventilation systems in veneer dryers. Traditional centrifugal fans, though effective in smaller setups, often struggle with the demands of large-capacity dryers—where large airflow, uniform temperature distribution, and energy efficiency are non-negotiable.

Axial Fans: The Optimal Choice for High-Capacity Dryers

Shine Machinery’s new axial fans are designed to outperform conventional centrifugal fans in large-scale drying operations. Drawing on decades of R&D expertise, Shine has optimized every aspect of axial fan technology to address the core needs of high-capacity veneer production:

1. Massive Airflow for Uniform Coverage

Large-capacity dryers require massive airflow to ensure every veneer sheet—whether stacked in layers or conveyed continuously—receives consistent heat and moisture removal. Shine’s axial fans deliver an industry-leading air volume of up to 120,000 m³/h (for a 1.2m diameter model), 30% higher than comparable centrifugal fans of the same power. This ensures uniform airflow distribution across the entire drying chamber, eliminating cold spots and over-drying risks.

2. Low-Pressure Design for Energy Efficiency

Shine’s axial fans operate at a low static pressure (500–1,800 Pa), perfectly matching the low-resistance architecture of modern high-capacity dryers. This design minimizes energy waste, reducing power consumption by 25–30% compared to centrifugal fans in similar applications. For facilities running 24/7, this translates to annual energy savings of up to $50,000 per dryer.

3. Turbulence-Free Operation for Consistent Quality

Traditional centrifugal fans generate turbulent airflow, leading to uneven moisture distribution and defects like warping or cracking. Shine’s axial fans, however, produce smooth, laminar airflow that glides evenly over veneer surfaces. Combined with Shine’s proprietary duct design (featuring adjustable louvers and diffusers), this ensures ±2% moisture uniformity across all sheets—critical for premium plywood grades.

Why Shine’s Axial Fans Stand Out

Shine’s innovation extends beyond raw performance. The new axial fans incorporate:

Smart Control Integration: Compatible with Shine’s IoT-enabled dryer control systems, allowing real-time adjustment of airflow speed and temperature via mobile apps.

Low-Maintenance Design: With no volute or complex guide vanes, maintenance is simplified to periodic blade cleaning—reducing downtime by 50% compared to centrifugal fans.

Durable Materials: Constructed from corrosion-resistant alloy steel, the fans withstand the high-humidity, high-temperature environment of veneer dryers, ensuring a service life of 10+ years.

Industry Outlook

“As the demand for large-capacity veneer dryers grows, manufacturers need solutions that balance performance, cost, and reliability,” said Mr. Li Wei, Chief Engineer at Shine Machinery. “Our new axial fans are not just an upgrade—they’re a game-changer. By delivering massive airflow, energy efficiency, and consistent quality, we’re empowering producers to scale their operations while maintaining the highest standards.”

With the launch of these advanced axial fans, Shine Machinery solidifies its position as a leader in woodworking technology. For manufacturers aiming to stay ahead in a competitive global market, Shine’s axial fan-equipped dryers offer a clear path to enhanced productivity, lower costs, and superior product quality.