What is the process of drying veneer?

Drying veneer is not just a step in veneer production. It is the heartbeat of quality veneer manufacturing.

If we rush it, the veneer sheets crack or warp. If we take too long, we waste energy and lose profit. The question every producer asks is simple: How long does it take, and what is the process of drying veneer? Let us walk through it together.

Why Dry Veneer Matters

Dry veneer is the foundation of strong plywood and laminated boards. Wet veneer cannot be glued and leads to weak bonds. Optimized drying gives us:

· Stable veneer sheets with the right moisture content

· Surfaces are ready to be glued without defects

· High-quality and consistent veneer production

· Energy savings with better drying results

When veneer drying works well, the final product shines. When it fails, the whole line suffers.

What Is the Process of Drying Veneer?

The veneer drying process is both science and art. We combine controlled drying air with careful timing. At its core, drying veneer involves four steps:

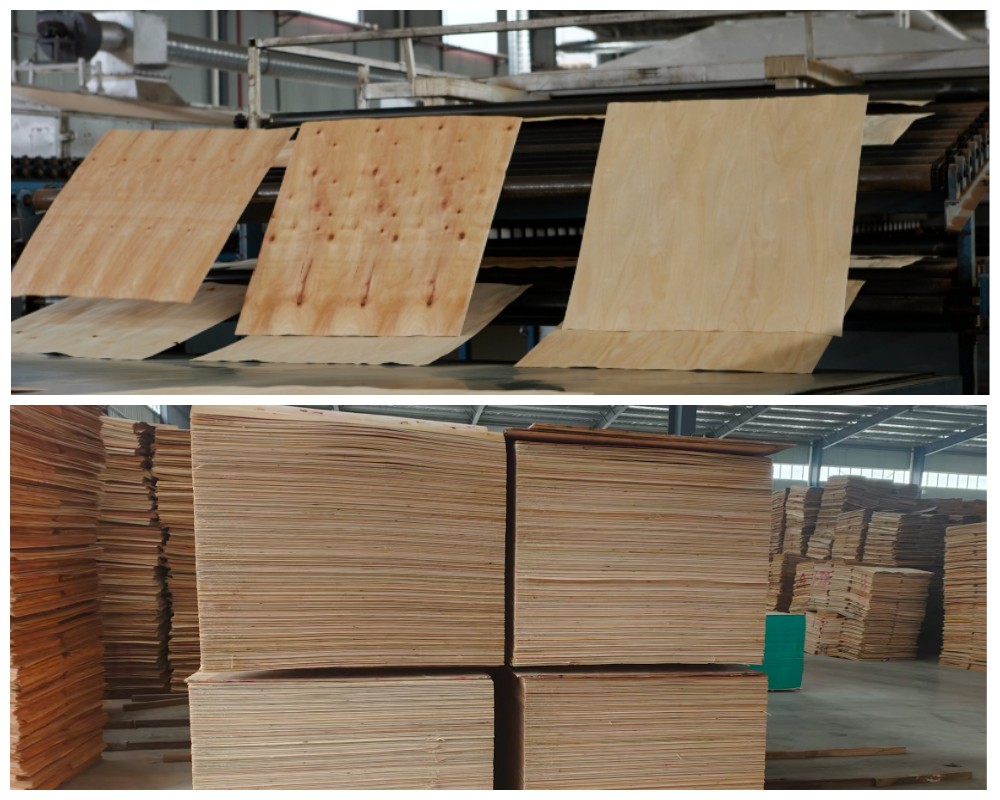

1. Feeding Wet Veneer – Sheets straight from the peeling line are full of moisture.

2. Heating and Circulating Air – Hot and humid air enters the system to evaporate water.

3. Moisture Removal – As the veneer moisture decreases, balanced drying air ensures even drying.

4. Final Conditioning – Sheets exit when the moisture content reaches 6% to 10%, ready to be glued.

Sounds simple? In practice, every second and every degree matters.

Step 1: Handling Wet Veneer

Wet veneer is fragile. We move it quickly to prevent surface mold or stress cracks. Stacking sheets too tight traps moisture. Keeping them loose makes drying easier.

Step 2: Controlled Heating

We use high temperatures, often between 140°C and 180°C. The hot and humid air surrounds the veneer sheets.

This removes moisture while protecting veneer quality. If we overheat, the veneer burns. If we underheat, drying stalls.

Step 3: Moisture Balance

Here lies the trick. The drying air must stay balanced. Too much heat creates brittle sheets. Too much humidity slows the drying process.

Our goal is a steady release of water. We measure veneer moisture continuously to fine-tune settings.

Step 4: Final Exit

Only a veneer with stable moisture content is a quality veneer. We check levels before stacking. If the sheets are too wet, they go back.

If too dry, they break during pressing. We want the sweet spot where the veneer is ready to be glued.

Factors That Decide Drying Results

The veneer drying process depends on several factors:

· Thickness of Veneer Sheets – Thin veneer dries faster. Thick veneer needs longer cycles.

· Type of Wood – Hardwoods behave differently from softwoods.

· Initial Moisture Content – Wetter sheets take more time.

· Drying Air Temperature and Flow – Uniform air ensures even drying.

· Machine Technology – An efficient Veneer Drying Machine ensures high quality results.

We never treat two batches the same. Each requires its own optimized drying plan.

Common Mistakes in Veneer Drying

1. Drying too fast – Causes cracks and curling

2. Leaving the veneer too wet – Creates bonding failures later

3. Ignoring uniform airflow – Produces uneven drying results

4. Overlooking final conditioning – Reduces veneer quality in production

Avoiding these pitfalls saves both time and money.

How Long Does Veneer Drying Take?

There is no single answer. Drying time varies depending on:

· Veneer thickness (0.5 mm may take minutes, 3 mm can take hours)

· Machine efficiency

· Drying air temperature and humidity

On average, veneer drying lasts 4 to 15 minutes for thin sheets. Thicker sheets may require 1 to 2 hours.

What matters is not speed but balance. Rushed drying sacrifices quality veneer. Slow drying drains energy.

Our Experience in Veneer Drying

We have seen many producers chase speed. They end up with brittle sheets that cannot bond. Others dry too cautiously and waste huge amounts of energy. From our journey, we believe in one principle: drying veneer is about precision, not haste.

Every batch teaches us something. Sometimes we celebrate the perfect moisture content. Sometimes we laugh at mistakes, like the time we overdried and turned veneer into potato chips. Trial and error built our understanding.

Why Optimized Drying Wins

Optimized drying gives more than just quality veneer. It also brings:

· Lower energy costs

· Consistent veneer production

· Higher profits from less waste

· Better performance in pressing and gluing

A well-tuned drying process is not only about machines but also about skill and experience.

Veneer Drying and the Future

Technology is moving forward. Modern dryers use sensors to track veneer moisture in real-time. AI adjusts drying air instantly for optimized drying.

The future promises faster cycles, smarter machines, and even higher drying results. Still, human judgment remains key. Veneer has personality. Machines only follow instructions, but people understand wood.

Final Thoughts

So, how long does it take to dry veneer? The real answer is: as long as it needs. Drying veneer is not about racing a clock. It is about finding the perfect balance between moisture content, drying air, and veneer quality.

If we respect the process, we get high quality veneer sheets ready to be glued. If we cut corners, we pay the price later. In the end, drying veneer is less of a job and more of a craft.