Thermal Oil Roller Dryer

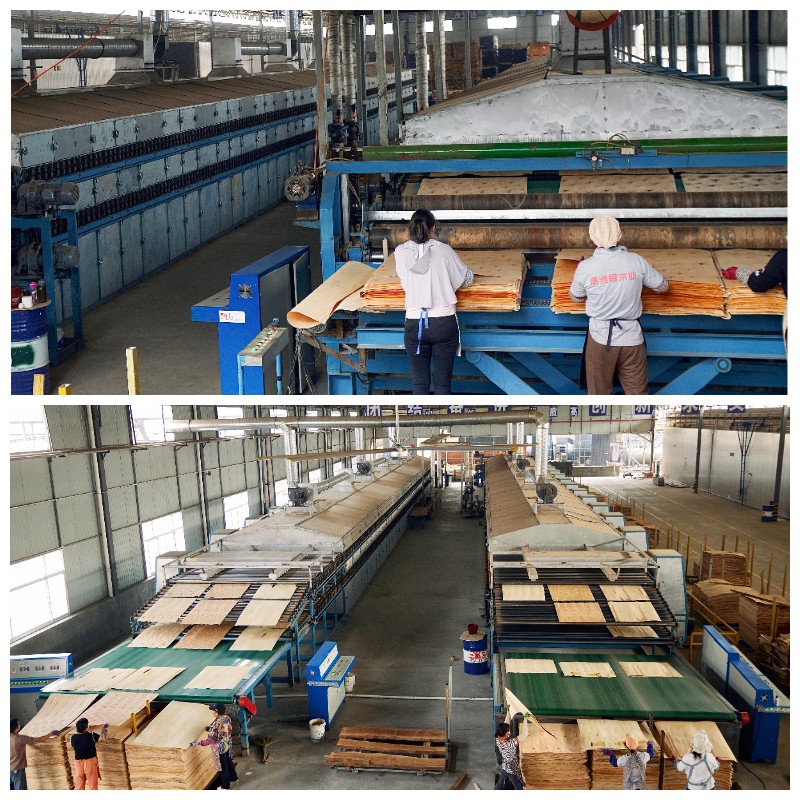

Shine Machinery’s Veneer Dryer Success Story: Efficient Medium-Output Drying for Eucalyptus Veneers in China.

In the heart of China’s thriving woodworking industry, where precision and efficiency drive production, Shine's veneer dryer has become a cornerstone of local processing operations. The installation showcases a 2 decks veneer dryer designed to meet the demands of medium-capacity eucalyptus veneer drying. With a total length of 44m, and a working width of 3.75m, this dryer is built to handle substantial volumes while maintaining optimal processing uniformity—critical for eucalyptus veneers drying, which require precise moisture control to avoid warping or cracking.

Technology That Delivers: Thermal Oil Heating & Smart Automation

At the core of this system is Shine ’s proprietary thermal oil dryer technology, chosen for its stable heat transfer and energy efficiency. Unlike other traditional dryers, the thermal oil system ensures consistent temperature distribution across the veneer layers, minimizing defects and maximizing product quality. Complementing this is the semi-automatic loading and unloading system, which streamlines workflow: operators simply guide veneers onto the infeed conveyor, and the system handles the rest—reducing labor costs and accelerating turnaround times.

Performance That Speaks: Daily Output at 80m3

For this client, consistency and volume matter. The dryer delivers an impressive daily output of 80m3—a sweet spot for medium-output woodworking facilities balancing capacity with operational costs. Whether processing raw eucalyptus logs or recycled veneers, the system maintains a steady throughput, ensuring timely delivery for downstream operations like plywood or LVL production.

Why Shine Machinery? Reliability for Medium-Output Producers

In an industry where “bigger” isn’t always better, Shine Machinery specializes in medium-output veneer drying solutions that punch above their weight. This customer case is a testament to our focus on:

· Adaptability: Customizable dimensions (length, width) to match facility layouts and production goals.

· Durability: Engineered for 24/7 operation, with robust components built to withstand the rigors of continuous veneer processing.

From eucalyptus to mixed hardwood veneers, Shine’s dryers are more than just machines—they’re partners in productivity. As the client puts it: “We needed a dryer that worked as hard as our team. Shine delivered.”

Ready to elevate your veneer drying game? Explore Shine Machinery’s range of thermal oil dryers and discover why we’re the go-to choice for woodworking professionals worldwide.

Model No | GTH30-44 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ 89 special shaft tube |

Heating area length | 40m |

Cooling area length | 4m |

Veneer thickness and size | 1.5-3mm (2500mm*1250mm) |

Veneer water moisture | Fresh Veneer to about 3% |

Heating material | Thermal Oil |

Drying capacity (m³/day) | About 60-65cbm, 24 working hours per day |

Veneer transport speed | 5-22m/min, 16A chain |

Power of Hot Air Blower | 5.5KW (10pc) |

Power of Traction Motor | 7.5KW, frequency control (2pc) |

Power of Cold air blower | 5.5KW (1pc) |

Total Power | 75.5KW |

Actual electricity consumption | About 50kwh per hour |