Veneer Grading System

Shine Veneer Grading System: Revolutionizing Precision and Efficiency in Wood Veneer Processing

The quality of wood veneer directly dictates the performance and market value of end products like plywood, furniture, and decorative panels. Traditional veneer grading relies heavily on manual inspection—a process prone to human error, time-consuming, and inconsistent in quality. Shine Veneer Grading System, a fully automated solution that combines advanced vision technology, moisture detection, and intelligent sorting to deliver unprecedented accuracy, speed, and scalability.

1. Visual Inspection

2. Moisture Content Detection

3. Veneer Grade Stacking

Visual Inspection: AI-Powered Precision for Surface Quality

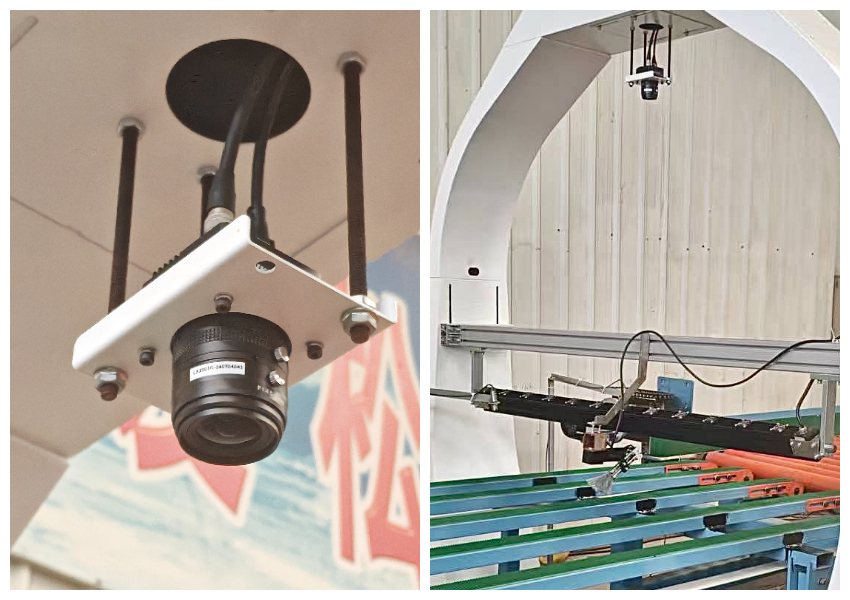

At the core of Shine’s Veneer Grading System is its high-definition (HD) visual inspection module, designed to eliminate the variability of manual assessment. Here’s how it transforms the grading process:

Dynamic, Real-Time Imaging: A high-resolution camera captures detailed, dynamic images of each veneer as it moves along the production line. This ensures no surface defect—from micro-cracks to knot patterns—is missed, even at high processing speeds.

AI-Driven Feature Analysis: Advanced AI algorithms autonomously process these images to model and classify surface features. The system automatically measures and counts critical parameters, including:

Defect dimensions: Accurately quantifying the area, size, and quantity of holes, cracks, or knots.

Color consistency: Detecting deviations from target color ranges to identify discolored or stained veneers.

Surface texture: Analyzing smoothness or roughness to flag irregularities that may affect bonding performance.

Automated Grading Feedback: Based on predefined classification standards (e.g., industry-grade A/B/C or custom client specifications), the system instantly determines the veneer’s grade. This grade information is seamlessly fed back to the production control system, enabling real-time adjustments to processing parameters or diversion of substandard veneers.

This AI-powered approach eliminates human bias and fatigue, ensuring consistent, objective grading. For manufacturers, this means fewer defective products, reduced rework costs, and enhanced brand reputation for quality.

Moisture Content Detection: Ensuring Optimal Material Performance

Moisture content (MC) is a critical factor in veneer quality—too high, and the veneer may warp or delaminate; too low, and it becomes brittle. Shine’s system integrates a precision moisture sensor to eliminate guesswork and ensure every veneer meets its target MC range:

Comprehensive MC Management: The sensor continuously detects, monitors, and analyzes the moisture levels of each veneer as it passes through the system. This data is logged for traceability and used to categorize veneers into predefined MC groups (e.g., 6–8% for premium furniture, 8–10% for construction plywood).

Intelligent Sorting for Efficiency: Veneers with MC outside acceptable ranges are automatically routed to the visual inspection module for re-evaluation. Here, operators can choose to either:

Reprocess the veneer (e.g., adjust drying parameters) if minor adjustments are feasible.

Divert it to a separate line for non-critical applications (e.g., packaging materials) if reprocessing is not cost-effective.

By integrating moisture detection with grading, Shine’s system ensures that only veneers with optimal MC levels proceed to downstream processes like gluing or lamination—minimizing waste and maximizing yield.

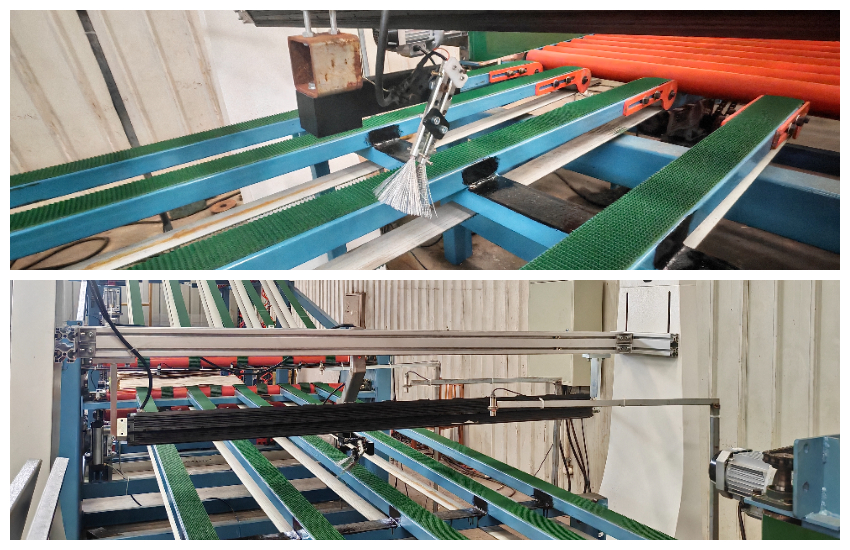

Veneer Grade Stacking: Flexible, High-Capacity Sorting

Once veneers pass visual inspection and moisture checks, they enter Shine’s intelligent stacking system, which is engineered for flexibility and scalability:

Multi-Grade Capacity: The system currently supports up to 8 distinct veneer grades, allowing manufacturers to segregate veneers by quality, species, or application (e.g., face veneers vs. core veneers). This segregation streamlines inventory management and simplifies order fulfillment.

Automated Sorting Logic: Using data from the visual and moisture modules, the stacking system automatically directs each veneer to its designated pile or bin. This eliminates manual sorting errors and reduces labor costs, especially in high-throughput facilities processing thousands of veneers per hour.

Adaptable Configuration: The stacking system is designed for easy reconfiguration, enabling manufacturers to adjust grade categories or add new ones as production needs evolve. Whether switching from furniture-grade to construction-grade veneers or accommodating a new client specification, the system can be reprogrammed in minutes.

Why Choose Shine’s Veneer Grading System?

Shine’s Veneer Grading System is more than just a set of tools—it’s a complete solution to the challenges of modern veneer processing. Here’s what sets it apart:

Unmatched Accuracy: AI-driven visual inspection and sensor-based moisture detection ensure grading consistency, reducing defects by up to 40% compared to manual methods.

Unrivaled Efficiency: Automated sorting and real-time data feedback cut processing time by 30–50%, boosting throughput for high-volume facilities.

Cost Savings: Minimized waste, reduced rework, and lower labor costs translate to a rapid return on investment (ROI) for manufacturers.

Scalability: The system’s modular design allows it to grow with your business, from small workshops to large-scale production lines.

In an industry where quality and efficiency are paramount, Shine’s Veneer Grading System redefines what’s possible. By combining AI, sensor technology, and intelligent sorting, it empowers manufacturers to produce higher-quality veneers, reduce costs, and stay ahead of market demands. Whether you’re producing premium furniture, durable construction materials, or specialized wood products, Shine’s system is your partner in precision and progress.

Elevate your veneer processing—choose Shine!

Shine Customer Relationship

Brazilian Agent visited Shine's newly developed Veneer Grading System, impressed by the AI Powered- visual inspection system.