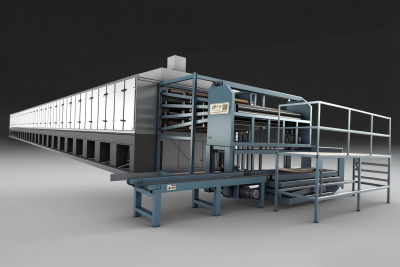

How to Choose a Right Veneer Dryer in your Plywood Production.

Key Factors in Roller Veneer Dryer Selection

When customers choose a roller veneer dryer, their decisions hinge on a range of critical considerations that directly impact production efficiency, product quality, and long-term operational costs. Below are the key priorities guiding their choices:

1. Core Performance & Thermal Efficiency

At the top of the list is thermal efficiency. Customers demand dryers with high heat transfer rates and stable insulation to ensure rapid, uniform heating while preventing over-drying— a common cause of wood cracks. Consistent thermal performance is non-negotiable for maintaining veneer integrity.

2. Processing Capacity

Matching equipment capacity to veneer specifications (dimensions, thickness) is essential. Overloading or underutilizing the dryer can compromise drying uniformity, leading to subpar results. Customers prioritize dryers designed to handle their specific veneer sizes without sacrificing efficiency.

3. Degree of Automation

Modern production lines favor automation. Customers seek roller veneer dryers with high automation levels—think compact designs, intuitive controls, and reduced manual intervention—to lower labor costs and minimize human error.

4. Safety & Stability

Safety features, including high-temperature alerts and emergency stop mechanisms, are critical. These safeguards prevent accidents during operation, protecting both personnel and equipment from damage.

5. Durability

Longevity matters. Customers opt for structurally robust dryers with low maintenance requirements, as this reduces lifecycle costs and ensures uninterrupted production over time.

6. Operating Costs

Energy efficiency is a key driver of long-term savings. Many customers prioritize dryers with heat pump technology or other energy-saving features to cut utility expenses.

7. Site Adaptability

Environmental factors, such as annual temperature and humidity, along with installation space constraints, influence model selection. A dryer that aligns with site conditions ensures optimal performance.

8. After-Sales Support & Technical Service

Reliable after-sales support—including professional installation, debugging, and regular maintenance—is a priority. Customers value vendors that offer proactive service to keep dryers running smoothly.

9. Spare Parts Availability

Easy access to wear parts (e.g., transmission components) is critical for minimizing downtime. Customers prefer suppliers with a robust parts network to ensure quick replacements.

In summary, selecting a roller veneer dryer requires balancing performance, efficiency, and practicality. By prioritizing these factors, customers can invest in equipment that enhances productivity, reduces costs, and supports sustained success in wood veneer production.