Why Veneer Dryer Is Indispensable in Plywood Manufacturing

In the production of plywood, the veneer dryer plays a role that is not merely supportive, but fundamentally critical to the entire manufacturing process. It serves as the bridge between raw veneer sheets and the high-quality, stable plywood panels demanded by the market. Without a properly functioning veneer dryer, the risk of defects, weak bonding, and inconsistent product quality increases significantly. The following points explain in detail why the veneer dryer is an essential piece of equipment in modern plywood production.

1. Ensuring Veneer Moisture Content Meets Process Requirements

Freshly peeled or sliced veneers typically contain a very high moisture content, often ranging from 60% to over 100%, depending on the species and cutting conditions. If such wet veneers are sent directly to the gluing and hot-pressing stages, several problems arise:

During hot pressing, excess moisture turns to steam rapidly, creating bubbles, delamination, and warping.

The adhesive may cure unevenly, leading to poor bond strength and reduced durability.

A veneer dryer uses controlled hot air circulation and efficient heat exchange to lower the moisture content of veneers to the range required for gluing (commonly 8%–12%, depending on wood type and adhesive). This creates a stable foundation for the next steps in the process.

2. Improving Bond Strength and Final Product Stability

When veneers have a uniform and appropriate moisture content, glue spreads evenly and penetrates properly into the wood structure. During hot pressing, the adhesive cures completely, forming strong bonds between layers. Conversely:

Over-wet veneers dilute the glue, weakening the adhesive layer.

Over-dry veneers absorb moisture from the glue too quickly, causing premature curing or incomplete bonding.

Additionally, dried veneers exhibit greater dimensional stability. After pressing and during later use, they are less likely to shrink, swell, or warp due to fluctuations in ambient humidity. This improves the long-term performance and appearance of the finished plywood.

3. Preventing Mold and Decay

High moisture content in veneers creates an ideal environment for mold and fungal growth, especially during storage or transport. Mold not only discolors the veneer surface but can also degrade its structural integrity. By reducing moisture to safe levels in a controlled drying process, the veneer dryer eliminates much of the free water that microorganisms need to thrive. This extends the usable life of both veneers and the plywood produced from them, ensuring better appearance and hygiene, which is particularly important for interior applications and export markets.

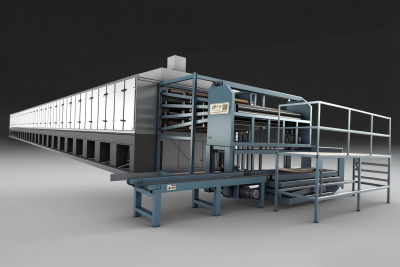

4. Boosting Production Efficiency and Energy Savings

Modern veneer dryers are equipped with high-efficiency heat exchangers, such as finned tube radiators that can exceed 92% thermal efficiency. Paired with hot air circulation systems, they can dry large volumes of veneer quickly and evenly. Benefits include:

Faster transition from raw veneer to ready-to-glue sheets, increasing overall line speed.

Reduced scrap and rework because fewer defects occur in later stages.

Lower energy consumption per cubic meter of dried veneer, thanks to optimized heat recovery and airflow design.

These improvements translate into higher productivity and lower operating costs for plywood manufacturers.

5. Ensuring Consistency Across Batches and Species

Plywood production often involves multiple wood species, veneer thicknesses, and suppliers, each with different initial moisture contents. The veneer dryer adjusts temperature, airflow, and residence time to bring all incoming veneers to a uniform moisture specification. This harmonization is critical for:

Consistent glue spread and penetration across different veneer types.

Uniform hot-press behavior, preventing warping or uneven stresses in the final panel.

Reliable quality control, allowing manufacturers to meet customer specifications batch after batch.

Conclusion: A Non-Negotiable Link in the Plywood Chain

The veneer dryer is far more than a preparatory machine—it is the quality gatekeeper in plywood manufacturing. By precisely controlling moisture content, it enables strong adhesion, dimensional stability, and defect-free panels. It also contributes to operational efficiency, energy conservation, and product uniformity. Skipping or undervaluing this step would lead to weak bonding, surface defects, dimensional instability, and ultimately, loss of market competitiveness. For any plywood producer aiming for reliable quality and sustainable production, investing in an advanced veneer dryer is not optional—it is essential.

Do you want me to prepare a step-by-step illustrated guide showing exactly where the veneer dryer fits into the whole plywood production line? That way, you can visually track its role from raw veneer to finished panel.