Is Wood Veneer Real Wood?

Introduction: Let’s Clear the Air

We hear this question all the time: Is Wood Veneer Real Wood?

Short answer—yes, it absolutely is. Veneer comes from real trees, just sliced thinner than your favorite pizza crust.

At Shine Machinery, we work with veneer production daily. We see how a thin slice of wood transforms into stunning furniture pieces. So today, we’ll break it down, no fluff, no jargon, just real talk about real wood.

What Is Wood Veneer?

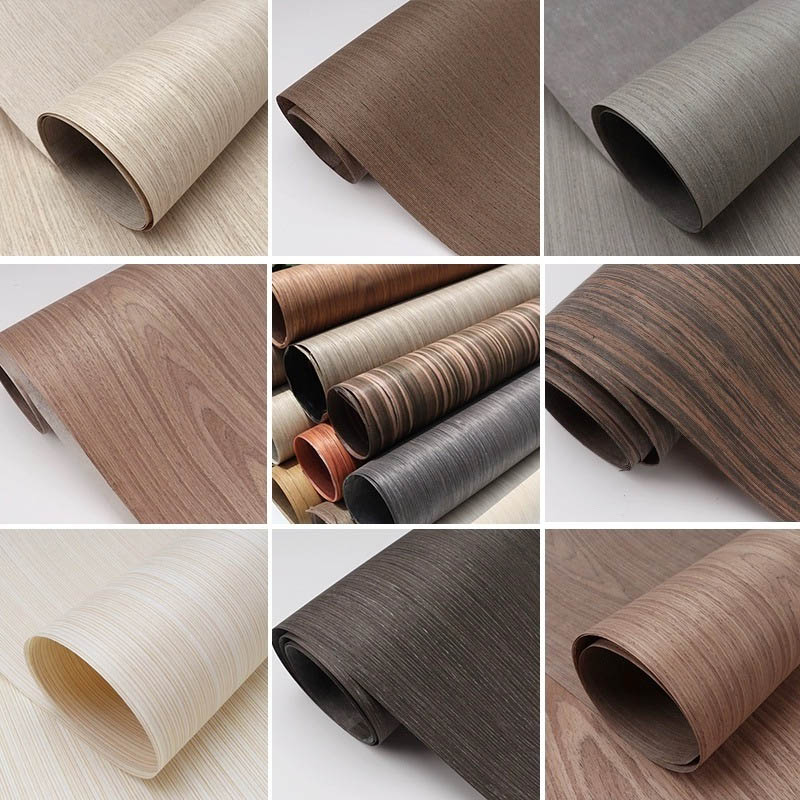

Wood veneer is a thin slice of wood cut from natural logs. Manufacturers peel or slice it carefully. The result? Beautiful veneer sheets with real grain patterns.

Unlike laminate, veneer uses genuine wood species. Oak, walnut, maple—you name it. That’s why the veneer surface looks authentic.

How Veneer Is Made

Veneer production follows a precise process:

Select premium logs

Soften wood with steam or hot water

Slice or peel thin sheets

Dry the veneer

Sort by veneer quality

Each step affects the final appearance. We obsess over this part because details matter.

Veneer vs Solid Wood

Here’s the big difference:

Solid wood piece = one thick block of wood

Veneer furniture = thin wood layer over a core

Both use real wood. The structure just changes.

Is Veneer Real Wood or Fake?

The confusion comes from thickness. Veneer is thin. But thin doesn’t mean fake. Think of it like sliced bread. Still bread, right?

Why People Doubt Veneer

Common myths we hear:

“Veneer is plastic.”

“It peels like wallpaper.”

“It’s cheap furniture.”

Nope. Not true. High-quality veneer lasts decades when made right.

Veneer Surface = Natural Beauty

Veneer keeps the original grain. You see knots, waves, and character. That’s nature showing off.

Solid Wood Furniture vs Veneer Furniture

We love solid wood furniture. It’s strong and timeless. But veneer furniture deserves respect, too.

Pros of Solid Wood

Heavy and durable

Can be refinished many times

Feels premium

Pros of Veneer Furniture

More stable

Uses less raw wood

Lower cost

Eco-friendly

Solid wood and veneer both have roles. We choose based on function, not ego.

The Drying Process: Why It Matters

Freshly sliced veneer starts as wet veneer. That moisture must go.

If not, problems happen later.

Why We Dry Veneer

Drying removes extra water. It prevents:

Warping

Mold

Cracking

We use advanced dryers at Shine Machinery. Controlled heat = better veneer quality.

Veneer Moisture Levels

Ideal veneer moisture stays between 8%–12%.

Too wet? Trouble.

Too dry? Brittle sheets.

That balance defines high-quality veneer.

How Veneer Is Used in Furniture

You see veneer everywhere, from cabinets to office desks.

Common Veneer Furniture Pieces

Dining tables

Wardrobes

TV stands

Office desks

Hotel furniture

Each piece of furniture looks like solid wood. But inside, it’s smart engineering.

Furniture Solid Wood Look

Veneer gives:

Rich color

Natural texture

Luxury vibes

Your guests can’t tell the difference. Trust us.

Solid Wood and Veneer: A Smart Combo

Many manufacturers mix both.

Solid frames + veneer surfaces = best of both worlds.

Why This Combo Works

Saves cost

Keeps strength

Reduces cracking

Looks premium

It’s like wearing sneakers with a suit. Unexpected but brilliant.

Choosing High Quality Veneer

Not all veneer is equal.

We see good, bad, and ugly daily.

Signs of Quality Veneer

Look for:

Even thickness

Smooth surface

Consistent color

No bubbles

Clean edges

Quality veneer feels solid. Cheap veneer feels flimsy.

Best Wood Species for Veneer

Popular choices:

Walnut

Oak

Maple

Cherry

Teak

Each wood species has its own personality. Walnut feels classy. Oak feels tough.

Veneer Drying: The Silent Hero

We rarely talk about it, but drying changes everything.

What Happens If Drying Fails?

Bad drying causes:

Curling edges

Surface cracks

Weak bonding

That’s why we invest in precision dryers. One degree off can ruin a batch.

How We Control Drying

At Shine Machinery, we:

Monitor temperature

Control airflow

Track veneer moisture

Adjust drying time

It’s part science, part art. And yes, we lose sleep over it.

Veneer vs Laminate: Big Difference

People confuse them all the time.

Feature | Veneer | Laminate |

Material | Real wood | Plastic |

Grain | Natural | Printed |

Repair | Can refinish | Hard to fix |

Feel | Warm | Cold |

Once you touch both, you’ll know.

Environmental Benefits of Veneer

Here’s the cool part. Veneer saves trees.

Why Veneer Is Eco-Friendly

Uses less wood

Maximizes each log

Reduces waste

Supports sustainability

One log can produce hundreds of veneer sheets.

That’s efficiency at its best.

Maintenance Tips for Veneer Furniture

Want it to last? Easy.

Daily Care

Wipe with a soft cloth

Avoid water spills

No harsh chemicals

Long-Term Care

Use coasters

Keep from direct sun

Control humidity

Treat it nicely. It will love you back.

Common Questions We Hear

Can Veneer Peel Off?

Yes, but only with poor glue or moisture damage.

Quality veneer stays put.

Can You Refinish Veneer?

Light sanding? Yes.

Deep sanding? Nope. It’s thin.

Is Veneer Cheaper Than Solid Wood?

Usually yes.

But premium veneer still costs money.

Our Honest Take on Shine Machinery

We work with veneer daily. We trust it.

We also respect solid wood.

Both materials serve different needs.

Your budget and style decide.

And remember—veneer is real wood. Just thinner. Like your patience on Monday mornings.

Final Thoughts

So, is wood veneer real wood?

Absolutely yes.

It comes from real trees.

It keeps natural grain.

It builds stunning furniture pieces.

Whether you choose solid wood furniture or veneer furniture, you’re choosing nature.

And that’s always a good decision.