Shine Machinery — Your Partner in Wood Processing Automation

Shine Machinery: Your Partner in Wood Processing Automation

For over two decades, the wood processing industry has been undergoing a quiet revolution, moving steadily from labor-intensive manual operations towards highly efficient, intelligent, and unmanned production lines. At the forefront of this transformation is Shine Machinery, a name that has become synonymous with innovation and reliability in the field of woodworking equipment. Since its establishment in 1999, the company has not merely followed but actively shaped industry trends, evolving from pioneering the concept of "green veneer production" in China to now launching its fourth-generation intelligent veneer production and drying lines. Shine Machinery doesn't just sell machines; it delivers comprehensive, future-proof solutions that define the benchmark for the modern woodworking plant.

A Legacy of Innovation: From Concept to Industry Standard

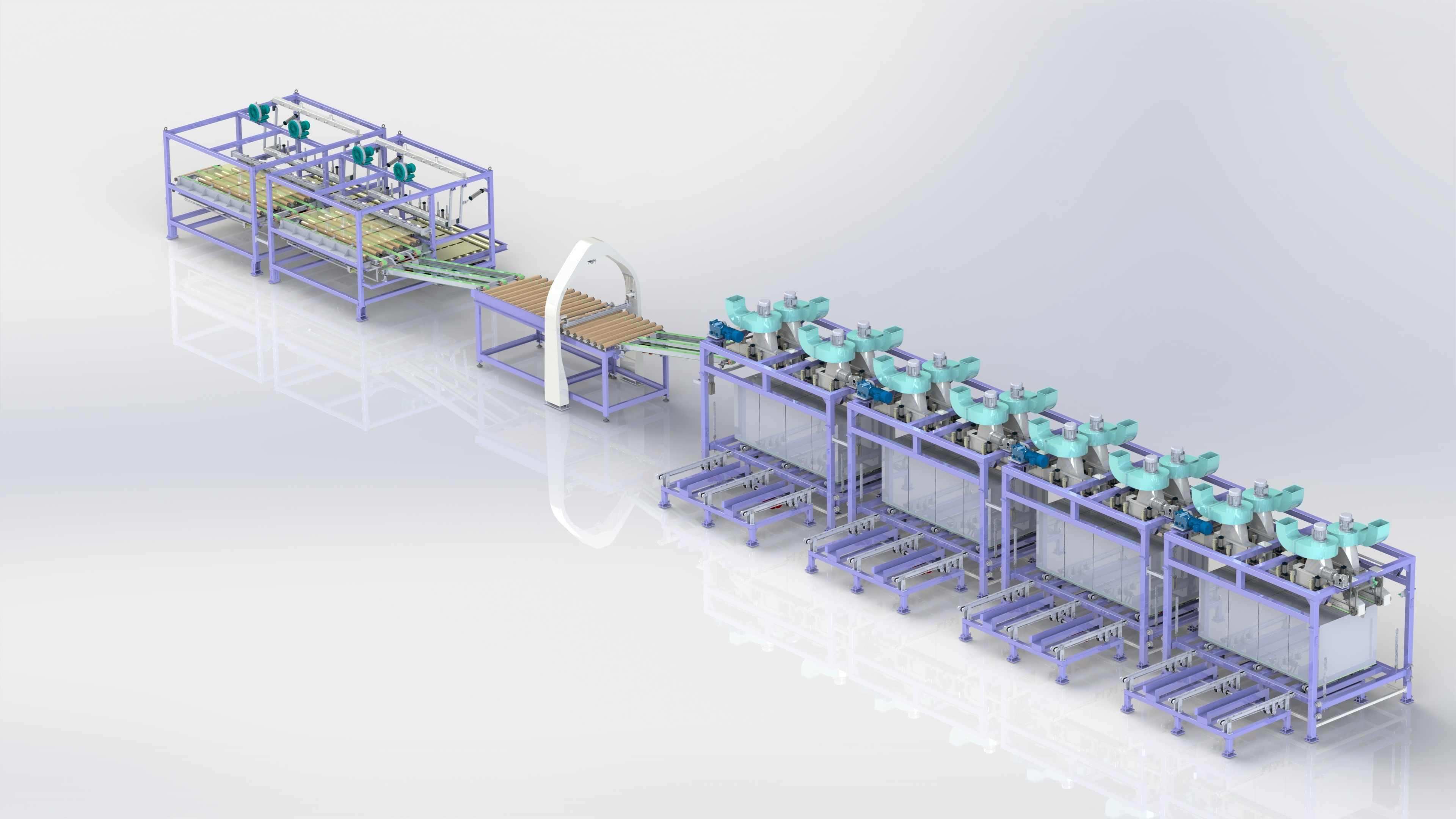

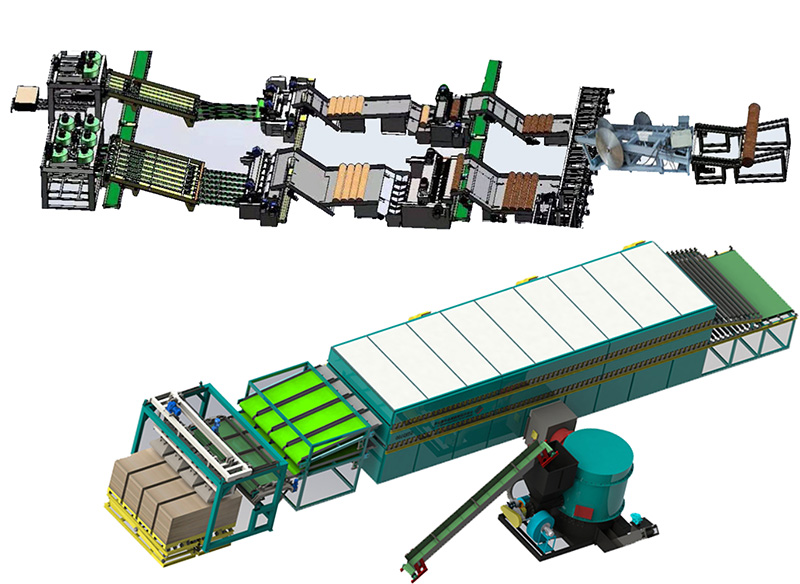

Shine Machinery's journey is a testament to its deep-rooted commitment to research and development. With annual R&D investments reaching the tens of millions and a strong focus on industry-academia-research collaboration, the company has consistently translated cutting-edge ideas into practical, high-performance machinery. This dedication is most evident in its flagship intelligent veneer production lines. These fully integrated systems represent the pinnacle of automation, seamlessly guiding the raw material through a sophisticated sequence: from the initial log break-down saw and log rounding machine, to the high-speed spindleless/spindle combination veneer lathe, followed by automated moisture content analysis, sorting, and stacking. The process continues with an automatic feeding system that charges a roller-type drying oven, and culminates with a vision-based sorting and robotic palletizing system. This end-to-end integration ensures maximum yield, consistent quality, and minimal manual labor.

Engineering Excellence: A Closer Look at Core Technologies

The true mark of a leader lies in the details of its engineering. Shine Machinery's equipment incorporates several proprietary technologies designed to solve persistent industry challenges.

The Automatic Feeding High-Speed Spindleless/Spindle Combination Veneer Lathe is a prime example of this innovative spirit. Recognizing that optimal veneer quality begins with precise log centering, Shine Machinery offers three advanced, automated centering solutions to suit various needs and budgets:

Contact Claw with Rotary Encoder Centering (X-Y Axis): A robust and accurate mechanical system.

Laser Probe System Centering (X-Y Axis): Offering non-contact, high-precision alignment for superior results.

Light Curtain Scanning System Centering: Providing a fast and efficient solution for comprehensive log profiling.

This flexibility ensures that every client receives the precise technology required for their specific raw material and quality targets.

Furthermore, Shine's Automated Roller Veneer Dryers are engineered for both performance and reliability. They feature intelligent temperature control systems that meticulously manage the drying curve, effectively preventing deformation and checking in high-moisture-content veneers. More impressively, Shine Machinery has directly addressed the significant maintenance demands traditionally associated with roller veneer dryer. By implementing maintenance-free designs for high-wear components such as roller bearings and the support bearings for the combustion furnace's rotating grate, they have drastically reduced downtime and operational overhead, allowing plants to run smoother and longer.

The One-Stop Solution Provider: More Than Just Machinery

Shine Machinery’s value proposition extends far beyond the manufacturing floor. It has built its reputation as a true one-stop solution provider, managing the entire project lifecycle from initial concept to full-scale operation. This holistic approach encompasses feasibility study and line design, precision manufacturing, professional installation and commissioning, and comprehensive operator training.

This "whole-process escort" service philosophy is backed by a robust global network. Whether serving domestic clients across China or international partners in dozens of countries, Shine Machinery places customer needs at the core of its operations. This is demonstrated through customized production line engineering, 24/7 remote technical support, on-site debugging assistance, and a solid one-year warranty on all equipment. The company understands that its success is intrinsically linked to the productivity and profitability of its clients.

As the global industry pivots decisively towards low-carbon, intelligent manufacturing, Shine Machinery stands ready. This established enterprise, with its 26 years of deep expertise, combines formidable technical prowess with a customer-centric culture. It is not just a supplier but a strategic partner, empowering wood processing businesses worldwide to navigate the complexities of digital transformation and achieve their goals for sustainable, high-efficiency production. For any manufacturer looking to build the factory of the future, today, Shine Machinery presents a proven and reliable pathway to get there.