How Thermal Oil Heater Dictate Dryer Output

The Heart of Drying: How Thermal Oil Heaters Dictate Dryer Output

In the world of industrial drying, where the goal is to efficiently remove moisture from materials like wood, food products, or minerals, one principle reigns supreme: heat is the fundamental driver. The entire drying process is, at its core, a massive exercise in heat transfer. The capacity of a dryer is not merely a function of its physical size, but of its ability to deliver sufficient thermal energy to evaporate water from the material. At the center of this crucial process lies a key component: the thermal oil heat exchanger. Think of it as the heart of the drying system. Just as a heart pumps life-giving blood to the body, the heat exchanger pumps vital heat into the veneer dryer. The amount of effective heat it can supply directly determines the machine's upper limit for removing moisture, and therefore, its ultimate production yield.

The Fundamental Role of Heat in Drying

To understand why the heat exchanger is so critical, we must first look at what veneer drying entails. Drying is not simply about blowing hot air on a wet surface. It involves providing enough energy to break the molecular bonds holding water within the material, turning liquid water into vapor. This phase change requires a significant amount of energy, known as the latent heat of vaporization. Evaporating one kilogram of water consumes a substantial and fixed amount of thermal energy.

Consequently, the production output of a dryer is fundamentally determined by the amount of useful heat that can be transferred to the material per unit of time. If you need to dry more material per hour, you must supply more heat per hour. There is no way around this basic thermodynamic law. Any limitation in the heat supply becomes an immediate and direct limitation on production capacity.

In a thermal oil (or thermal fluid) heating system, heat travels along a specific chain. This chain helps visualize the heat exchanger's pivotal role:

The Heat Source: A burner (using gas, oil, or biomass) or an electric heater generates heat by raising the temperature of the thermal oil.

The Heat Carrier: The thermal oil acts as an efficient, high-temperature liquid carrier, moving heat from the source to the point of use.

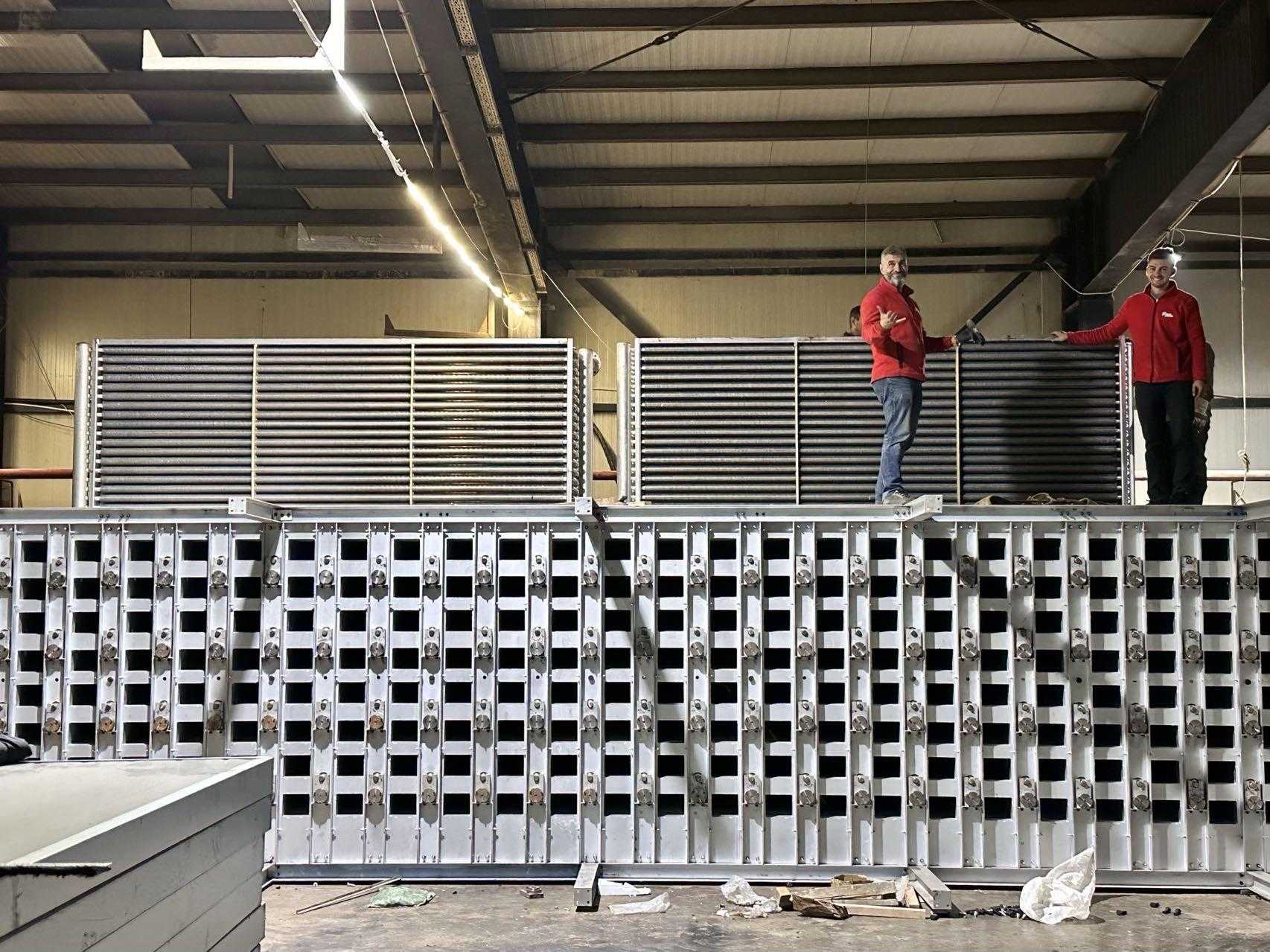

The Heat Exchanger: This is the critical interface where the heat is finally transferred to the drying process. The thermal oil flows through tubes inside the exchanger, while ambient air is blown across these hot tubes. The air is heated, becoming the hot, dry medium that will enter the dryer cabinet.

Therefore, the temperature, volume, and total thermal energy of the hot air entering the veneer dryer are entirely dependent on the performance of the heat exchanger. The system is only as strong as its weakest link. A powerful burner is useless if the heat exchanger cannot efficiently transfer that generated heat into the air.

How a Failing Heat Exchanger Strangles Production

The negative impact of a subpar heat exchanger manifests in several ways, each creating a bottleneck that throttles production.

Scenario 1: Low Heat Transfer Efficiency (e.g., due to fouling or poor design)

The Symptom: The inlet temperature of the thermal oil is high (as measured by the control system), but the outlet temperature of the heated air is disappointingly low. This indicates poor efficiency.

The Consequence: The resulting hot air has a lower temperature, meaning it has a reduced capacity to carry heat (lower specific enthalpy). When this less energetic air hits the wet material, it cannot rapidly evaporate moisture. To achieve the required final moisture content, the material must remain in the dryer for a longer period. This extended drying cycle directly results in lower production per hour.

Scenario 2: Insufficient Heat Transfer Capacity (e.g., undersized area or low oil flow)

The Symptom: The air temperature might reach the desired setpoint, but the overall quantityof heat available is inadequate. It's like a high-temperature but very small flame.

The Consequence: The system cannot supply enough total thermal energy to handle a large, continuous feed of wet material. The dryer becomes "heat-starved." Some material may not receive enough heat, leading to incomplete and uneven drying. This not only limits the maximum achievable output but can also cause significant quality control issues, with some batches being over-dried and others remaining damp.

Scenario 3: The Critical Balance Between Temperature and Airflow

The total heat required for drying (Q) can be simplified by the formula:

Q = Airflow Volume × Specific Heat of Air × (Hot Air Temperature - Ambient Temperature)

To increase production, you must increase the total heat (Q) input. This can be done by:

Increasing the hot air temperature.

Increasing the airflow volume.

Or both.

However, a poorly performing heat exchanger creates a lose-lose situation. If you try to increase airflow to carry more heat, the limited thermal exchange will cause the output air temperature to drop significantly. Conversely, if you prioritize maintaining a high temperature, you cannot increase the airflow enough to distribute that heat across a larger volume of material. An efficient heat exchanger is precisely engineered to find the optimal balance between high air temperature and high airflow volume, thereby maximizing the total useful heat output (Q) . An inefficient one cannot achieve this balance, placing a hard cap on production capacity.

Conclusion: The Heart of the Matter

In summary, the production chain is clear and unforgiving:

Heat Source → Thermal Oil → Heat Exchanger → Hot Air → Material (Moisture Evaporation) → PRODUCTION

If the heat exchanger—the heart of the system—fails, the entire operation suffers. The consequences are inevitable: slower drying speeds, higher energy consumption per unit of product, reduced hourly output, and unstable product quality.

Therefore, proactive maintenance of the thermal oil heat exchanger is not just a technical task; it is a fundamental business strategy for maximizing productivity and profitability. Regular cleaning to prevent fouling, vigilant monitoring of the temperature differential between the thermal oil and the output air, and ensuring proper oil flow are all essential practices to keep this vital component—and by extension, your entire drying operation—performing at its peak.