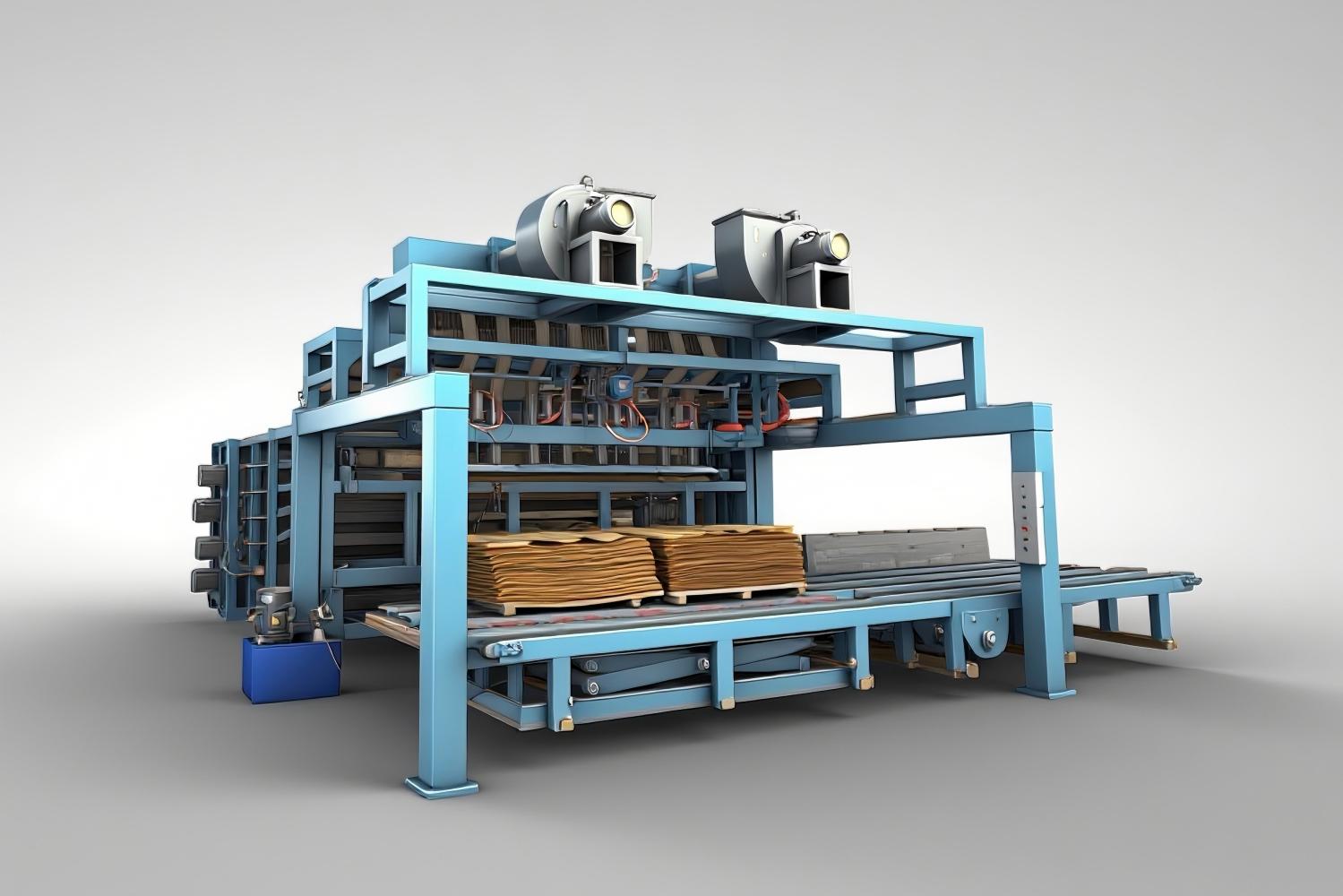

Automated Roller Dryer

Shine Machinery’s European-Grade Birch Veneer Dryer: Precision, Sustainability, and Compliance Redefined in Latvia

In Latvia’s thriving woodworking industry—where birch, a fast-growing, versatile hardwood, drives demand for high-quality veneers—drying efficiency and environmental compliance are non-negotiable. As European markets tighten emission standards and manufacturers seek to minimize waste, a new era of drying technology is emerging. Shine Machinery’s patented birch veneer dryer, now setting industry benchmarks in Latvia.

1. 4 decks 36m dryer

2. Daily capacity of 110m3

3. Working width at 3.5m (customization)

4. Biomass heat source (burn waste wood)

Powering Latvia’s Birch Veneer

The 4 decks veneer dryer (36m in length, 3.5m in working width) is tailored to the unique demands of birch veneer production. For a leading local woodworking enterprise, it’s not just a dryer—it’s the key to scaling production while meeting strict EU environmental regulations. With a steady daily output of 110 m3, this system is transforming how birch veneers are dried, turning seasonal challenges into opportunities for growth.

Birch veneers, prized for their fine grain and light color, demand careful drying to avoid discoloration, warping, or moisture retention. Traditional dryers often struggle with birch’s rapid moisture release, risking quality inconsistencies. Shine Machinery’s solution? A birch-specific drying profile engineered into the machine’s DNA:

Optimized airflow and temperature zones: The dryer’s multi-layer design ensures uniform heat distribution, with adjustable parameters calibrated for birch’s 3-8% target moisture content. This eliminates over-drying in the core layers and under-drying on the edges—common pitfalls in generic dryers.

Low-stress handling: The 3.5m working width and automated conveying system gently move veneers through the chamber, minimizing mechanical stress that can cause surface cracks in this delicate wood.

Waste-to-Energy Synergy: Biomass Burner Meets Birch Scrap

At the heart of the dryer’s efficiency is Shine’s biomass burner, which transforms waste wood—a byproduct of birch veneer slicing (bark, offcuts, and trimmings)—into a sustainable energy source. Here’s how it elevates operations:

Closed-loop cost savings: The client’s mill generates up to 8 tons of birch waste daily. Instead of paying for disposal or relying on costly natural gas, this scrap fuels the biomass burner, reducing energy costs by 40% and eliminating waste hauling fees.

Smart fuel feeding: The burner’s automated system adjusts fuel input based on real-time drying demand, ensuring consistent heat output even as birch veneer batches vary in thickness or initial moisture levels.

EU-Compliant Emission Control: Shine’s Patent Water-Film Dust Removal + Heat Exchanger

In Europe, compliance with strict emission standards (like the EU Best Available Techniques Reference Document, BREF) is mandatory. Shine Machinery’s dryer goes beyond compliance—it sets a new bar for clean drying:

1. Patent Water-Film Dust Removal System

Birch waste, when burned, can release fine particulates and volatile organic compounds (VOCs). Shine’s proprietary water-film technology neutralizes this risk:

· A rotating drum coated with a thin water film captures dust and particles as flue gas passes through, scrubbing the air clean before it enters the heat exchanger.

· This system reduces particulate matter (PM) emissions by 99.8%, ensuring zero visible smoke and compliance with EU’s 20mg/Nm³ PM limit.

2. Special Heat Exchanger for Stepwise Dust Reduction

Complementing the water-film system is Shine’s patented heat exchanger, designed to further purify exhaust gases.

Performance That Drives Profit: 110 m3 Daily of Premium Birch Veneers

For the Latvian client, consistency is key. This dryer delivers 110m3 of uniformly dried birch veneer daily, even during peak production months. Whether processing 3mm-thin decorative veneers for furniture or 8mm-thick blanks for construction laminates, the system maintains tight moisture tolerances (±0.5%), reducing downstream rejects by 30% and keeping laminators, finishers, and customers satisfied.

Why Shine Machinery? Built for Europe’s Forestry Vision

In a market where sustainability and efficiency are twin priorities, Shine Machinery’s dryers stand out:

· Birch expertise, engineered in: From the initial consultation to final installation, our team collaborates with European birch processors to refine settings for local wood characteristics—no one-size-fits-all solutions here.

· Future-proof compliance: The water-film dust removal and heat exchanger systems are designed to meet not just current EU standards, but future tightening regulations, protecting your investment for years to come.

· Low-maintenance reliability: Corrosion-resistant stainless steel components, sealed bearings, and easy-access service points ensure the dryer operates 24/7 with minimal downtime—even in Latvia’s humid, seasonal climates.

Elevate your birch veneer production with Shine Machinery’s European-compliant veneer dryer—where waste becomes energy, precision ensures quality, and sustainability drives profit.

The customer Products

Model No | GTH35-36 |

Working Width | 3.5m |

Deck | 4 |

Roller material | Q235B, φ 102 special shaft tube |

Heating area length | 32m |

Cooling area length | 4m |

Veneer thickness and size | 1.5mm; 2.2mm (2600mm*1350mm) |

Veneer water moisture | 70-80% to about 6-8% |

Heating material | Biomass Burner |

Drying capacity (m³/day) | 110 |

Veneer transport speed | 5-22m/min, 16A chain |

Power of Hot Air Blower | 4KW (32pc) |

Power of Traction Motor | 5.5KW, frequency control (4pc) |

Power of Cold air blower | 4KW (4pc) |

Power of Auto Loading Inlet | 21KW |

Total Power | 187KW |