Shine Biomass Burner

Shine Biomass Burner: Promoting new development of energy-saving and environmentally friendly production. The innovative combustion technology has strong fuel adaptability, and biomass pellets, wood chips, straw, etc. can all be burned efficiently. By optimizing the furnace structure and air intake system, the combustion efficiency is as high as over 90%.

1. Fuel Flexibility & Cost Savings

2. User-Friendly Design

3. Reliable Performance

The advantages of Shine Machinery’s biomass burner?

Waste wood is used as fuel to save costs: broken waste wood, black bark, white bark, dry and wet wood

High safety: no pressure, not a boiler pressure vessel, high safety, no need for approval from the special equipment department

Easy to install and use: easy to install, suitable for use with dispersed dryers

Convenient to maintain and clean: There is a place to store ash under the fire-dividing furnace, which needs to be cleaned regularly, with a frequency of two weeks or one month, depending on the type of fuel and the combustion situation.

Technical performance and features of Shine’s biomass burner:

Accurate air distribution ratio can ensure stable, full and efficient combustion of fuel.

Innovative grate design can achieve full mixing of fuel and overall flame stability.

Water circulation cooling system to ensure continuous high-temperature operation of the burner.

All parts are easy to disassemble, repair and maintain.

Feed, main air, air distribution and grate all use variable frequency power to ensure the ratio of fuel, flame and air volume, and ensure safe and efficient combustion.

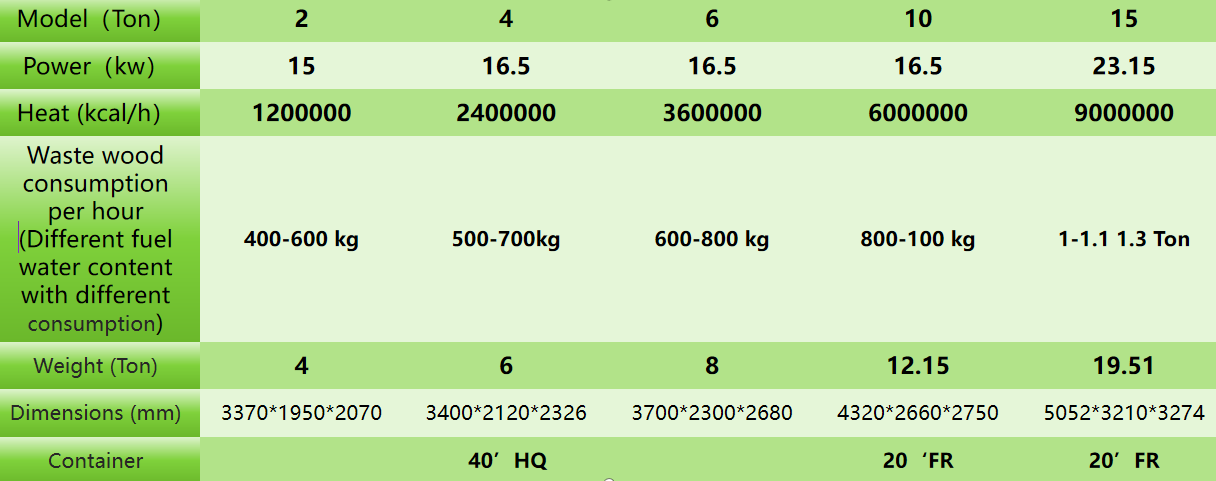

Parameters and fuel consumption of biomass burner:

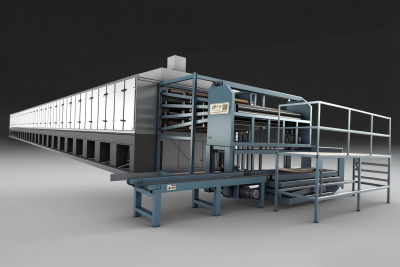

Ideal for workshops, small factories, or large-scale veneer mills:

Shine’s biomass burner adapts to your production scale. Pair it with our veneer dryers to create a closed-loop system where waste fuels the process, driving sustainability and profitability hand in hand.