Mesh Belt Dryers Elevate Veneer Quality

Sub-headline: How Advanced Drying Technology Protects the Fragile Beauty of Engineered Wood Veneer

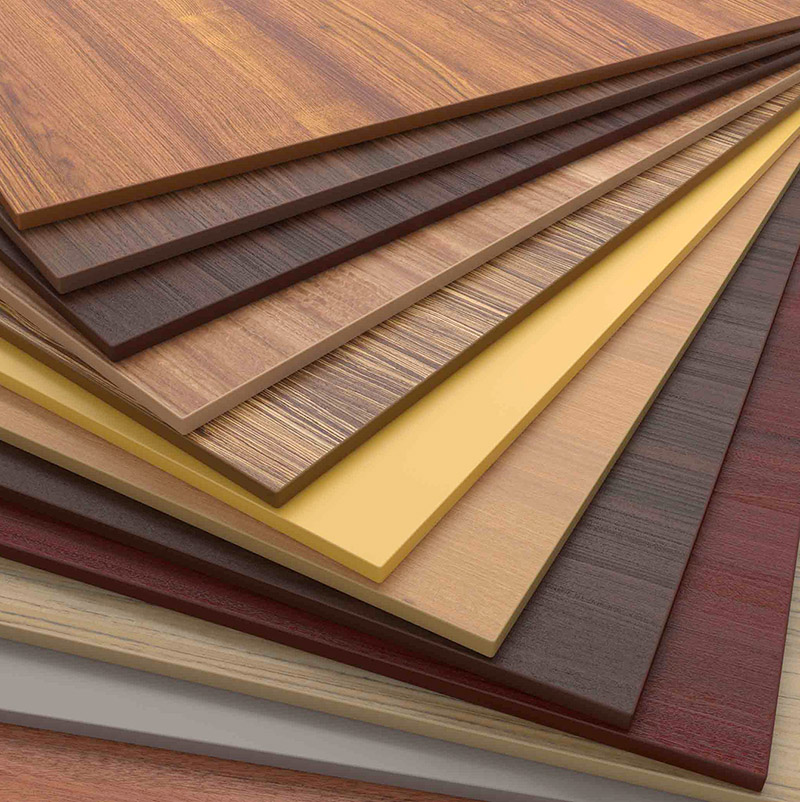

In the relentless pursuit of creating the perfect surface, the engineered wood veneer industry faces a critical challenge: preserving the exquisite, yet incredibly fragile, result of complex manufacturing processes through the final and most perilous stage—drying. Unlike its solid wood counterparts, engineered veneer is a masterpiece of transformation, born from fast-growing poplar or birch that undergoes a meticulous journey of peeling, bleaching, dyeing, layering, gluing, and slicing. The final product, a wafer-thin sheet boasting the luxurious grain of rare woods like ebony or rosewood, commands a premium price. However, this beauty is skin-deep and supremely vulnerable. Any mishandling during drying can lead to irreversible defects, turning a high-value product into worthless scrap. This is the precise reason why the mesh belt veneer dryer has become the undisputed gold standard for drying these delicate materials, representing a critical convergence of material science and industrial engineering.

The unique nature of engineered wood veneer dictates its "precious cargo" status and imposes non-negotiable demands on the drying process. With thicknesses typically ranging from a mere 0.2mm to 0.6mm, the material possesses minimal structural integrity. Its surface, having been chemically treated and re-engineered, is exquisitely sensitive to pressure, rapid temperature fluctuations, and uneven moisture removal. The stakes are high; a single crease, a hint of discoloration from a scorched dye, or a slight curl can render a sheet unusable. Traditional drying methods, such as roller dryers or vacuum systems, are simply inadequate for this task. Roller dryers apply crushing pressure that creates permanent impressions and stretches the substrate, while vacuum systems can struggle with uniform heat distribution and are less efficient for high-volume production. The industry needed a solution that was simultaneously gentle, precise, and productive—a solution embodied by the mesh belt veneer dryer.

The operational principles of a mesh belt veneer dryer are elegantly designed to mitigate every risk associated with drying such a sensitive product. At its core, the system is a continuous conveyorized tunnel dryer. The veneer sheets are laid flat onto one or more layers of a perforated metal mesh belt, which transports them smoothly through a series of precisely controlled temperature zones. This seemingly simple innovation yields profound benefits.

Firstly, the gentle, pressure-free support is transformative. By eliminating physical contact points beyond the flat plane of the mesh, the dryer prevents the scratches, dents, and tensile deformation commonly seen in other systems. This ensures the surface remains immaculate, preserving the intricate, simulated grain pattern that defines the product's value.

Secondly, the precision-controlled hot air circulation is paramount. High-velocity fans drive heated air through the permeable belt, bathing both the top and bottom surfaces of the veneer in a uniform stream. This "through-drying" mechanism is crucial for achieving balanced moisture evaporation from both sides simultaneously. It is the primary defense against warping, cupping, and the dreaded "S-curve" deformation, guaranteeing the flatness required for seamless application onto panels. Furthermore, the temperature and humidity within the chambers can be programmed into sophisticated profiles, enabling a slow, controlled cure that protects heat-sensitive dyes from fading or decomposing and prevents the adhesive layers from failing or cracking.

Finally, the high-efficiency continuous production capability addresses the economic imperative. An automated loading system feeds the veneer onto the mesh belt, which then carries it through the drying cycle before an unloading mechanism collects the perfectly dried sheets. This creates a seamless, 24/7 manufacturing workflow that dramatically boosts output and reduces labor costs. The consistency of this continuous process ensures that every batch meets the exact same stringent quality standards, fostering reliability and brand reputation.

As the global demand for sustainable, high-quality decorative surfaces grows, manufacturers are increasingly recognizing that investing in advanced drying technology is not an expense, but a direct investment in product integrity and profitability. The mesh belt veneer dryer stands as a testament to this philosophy, transforming a potential point of failure into a fortress of quality control. For producers of premium engineered veneer, choosing this technology is a clear statement of commitment to excellence, ensuring that the beauty painstakingly engineered into every sheet is delivered flawlessly to the final application.