News Center

The Truth About Veneer DryersVeneer dryers are the unsung heroes of the plywood and furniture industry. While the gleaming CNC lathes and pressing lines often steal the spotlight, it is the dryer that holds the ultimate power over product quality, production efficiency, and your bottom line. But…

2025/11/14 17:05

The Heat That Builds Better WoodWhen we first built our wood processing plant dryer, we didn’t just chase numbers. We chased perfection.Every piece of wood tells a story — if you dry it wrong, it warps, cracks, and loses its soul. But when you dry wood right, it transforms into a strong, stable…

2025/11/12 10:15

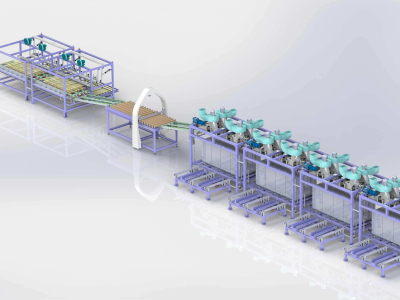

Shine Machinery: Your Partner in Wood Processing AutomationFor over two decades, the wood processing industry has been undergoing a quiet revolution, moving steadily from labor-intensive manual operations towards highly efficient, intelligent, and unmanned production lines. At the forefront of this…

2025/11/10 10:37

What Is an Oak Veneer?So, what is an oak veneer really? Imagine taking a thin slice of oak wood, revealing its gorgeous grain patterns, and gluing it onto a sturdy panel. That, in essence, is an oak veneer—a clever fusion of natural wood aesthetics and engineered durability. We love oak veneer…

2025/11/07 16:57

The Heart of Drying: How Thermal Oil Heaters Dictate Dryer OutputIn the world of industrial drying, where the goal is to efficiently remove moisture from materials like wood, food products, or minerals, one principle reigns supreme: heat is the fundamental driver. The entire drying process is, at…

2025/11/05 10:21

We at Shine Machinery are excited to walk you through how to make wood veneer from solid wood to finished veneer sheets. As a manufacturer specializing in the veneer drying machine, we bring you real insight into veneer production—a mix of craft, tech and industrial precision. You’ll find humor,…

2025/10/29 11:24

Why Uneven Moisture in Dried Veneers Significantly Impact Plywood Production?The uniformity of moisture content in dried veneers is a critical factor in plywood manufacturing, directly affecting bonding quality, dimensional stability, and production efficiency. Here’s a detailed breakdown of its…

2025/10/22 10:55

The Critical Wait: Why Veneer Needs to Rest Before DryingIn the high-speed world of wood processing, efficiency is king. Every minute saved on the production line translates to increased output and profitability. It’s natural to want to move freshly peeled veneer from the lathe directly into the…

2025/10/17 09:52

Introduction: Let’s Talk Wood, Not Boring StuffWe get it. When someone says veneer or plywood, your mind probably jumps to “just wood panels.” But trust us, there’s a lot more behind those smooth sheets and sturdy boards than meets the eye.At Shine Machinery, we’ve spent years crafting, drying, and…

2025/10/15 15:47

Heavy Roller Dryers Ensure Superior Veneer QualityIn the competitive world of wood processing, the choice of drying equipment plays a pivotal role in determining the final product quality and operational efficiency. Recent feedback from leading manufacturers underscores a critical trend: the…

2025/10/11 16:56

Introduction: More Than Just Dry WoodWhen people ask us what a veneer drying machine we usually smile. To us, it is more than a giant oven. It is the heart of veneer production. Without it, veneer sheets stay soggy. Moisture content runs wild. Glue refuses to stick. And your so-called high-quality…

2025/09/29 17:06

Introduction: A Question We Hear All the TimeWe hear it at trade shows. We hear it in our inbox. “Is veneer actually wood?” Some people swear it is. Others think veneer is fake and cheap.The truth sits somewhere between myth and reality. And trust us, once you know how veneer works you may never…

2025/09/28 15:39