6 Deck Veneer Dryer

Shine Machinery’s 6 Deck Veneer Dryer: Redefining High-Output Veneer Drying for Global Woodworking

In the competitive world of wood-based panel production, efficiency and capacity often determine success. For plywood manufacturers, furniture makers, and construction material suppliers, a dryer that delivers both speed and consistency is the holy grail. Shine Machinery—the first Chinese manufacturer to crack the code on 6-deck veneer drying technology—now redefining high-output veneer drying with its groundbreaking 6-deck model. This innovation isn’t just a leap forward for Shine; it’s a milestone in China’s industrial machinery history, built in collaboration with Grenzebach China, to set new global benchmarks.

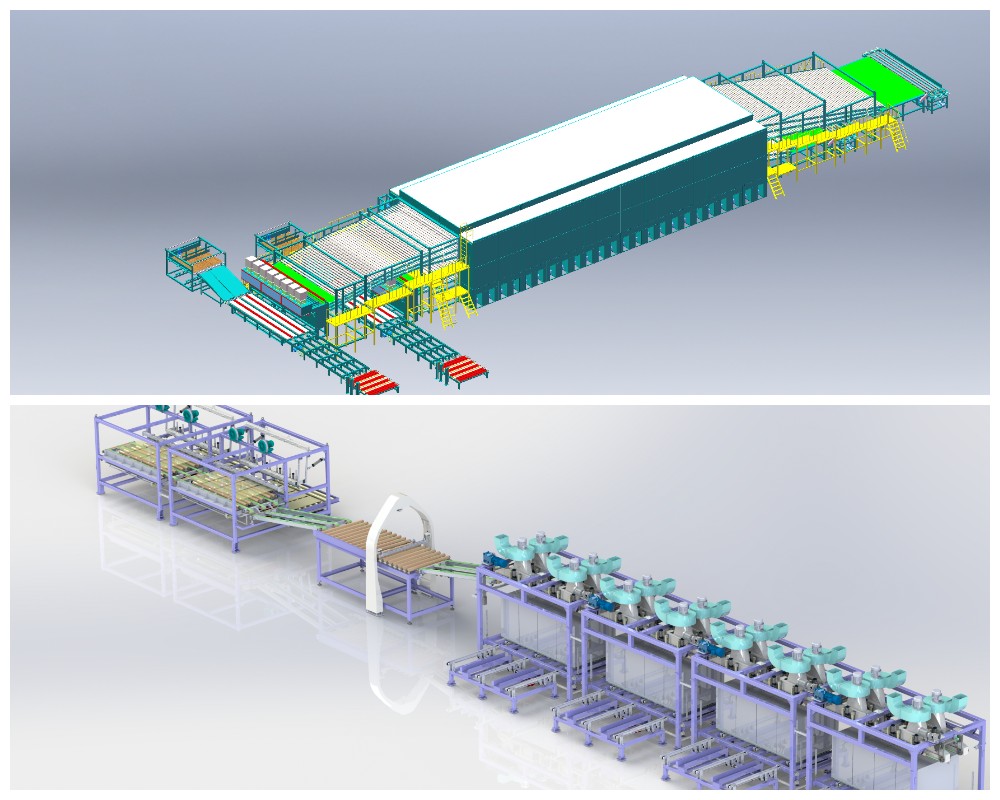

6 Deck Design Meets Industrial-Scale Capacity

Shine’s 6-deck veneer dryer (42m in length, 6m in working width). For plywood producers, this means unprecedented throughput: with a staggering daily output of 15-18m3 per hour, it slashes drying cycles by 40% compared to traditional 2 or 4-deck models. Whether processing thin decorative veneers for furniture or thick blanks for construction plywood, this dryer delivers consistent, high-quality results at scale.

Why 6 Decks? The Science of Space, Speed, and Efficiency

Flexibility in Fuel: Adapt to Any Energy Source

To meet diverse client needs, the 6 Deck Veneer Dryer supports multiple heat sources: thermal oil, steam, or biomass burner etc. This versatility is a game-changer for regions with varying energy costs or sustainability goals:

Thermal oil systems: Ideal for high-temperature, stable drying (e.g., for dense hardwoods like beech or oak).

Steam heating: Perfect for moisture-sensitive veneers requiring gentle, controlled drying (e.g., birch or poplar).

Biomass burners: A cost-effective, eco-friendly option for mills with access to waste wood, reducing reliance on fossil fuels.

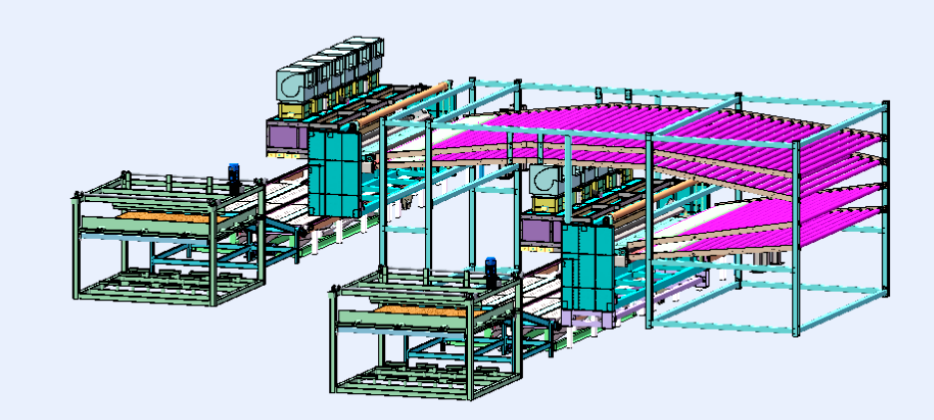

Automation Redefined: Two Sets of Fully Automated Loading Systems

Downtime is the enemy of high output. That’s why Shine integrated two sets of fully automated loading systems into the 6-deck design:

Upper three decks: Loaded via a high-speed conveyor that feeds veneers seamlessly from the input line.

Lower three decks: Equipped with a separate, synchronized loader to avoid bottlenecks.

Collaboration with Grenzebach China: Engineering Excellence Backed by Global Expertise

Developed in partnership with Grenzebach China, a leader in industrial drying solutions, this 6 Deck Veneer Dryer combines Shine’s deep understanding of Asian woodworking needs with Tiefenbach’s cutting-edge thermal engineering. The result? A machine that meets not just domestic standards, but global expectations for reliability, energy efficiency, and precision.

High Output, Higher Profits: What This Means for Your Business

For plywood mills, furniture manufacturers, and wood composite producers, the 6-deck veneer dryer translates to:

Reduced labor costs: Automated loading/unloading cuts workforce needs by 50%.

Lower energy bills: Axial flow fans and multi-source heating optimize energy use, slashing operational costs by 25-30%.

Faster time-to-market: 15-18m3 per hour output accelerates production cycles, enabling quicker delivery to clients and capturing more orders.

Peru customer visited Shine 6 Deck Veneer Dryer

Shine Machinery’s 6-Deck Veneer Dryer isn’t just a machine—it’s a revolution in high-capacity veneer drying.

The Technical Parameter

Model | GTH612-42 |

Deck | 6 |

Working Width(M) | 6120mm |

Hot Air Section(M) | 36m(2m/section, 18sections in total) |

Cold Air Section(M) | 6m (2m/section, 3 section in total) |

Veneer Species & Thickness(MM) | 0.8mm above |

Veneer Size | 2*4ft; 4ft*4ft; 4ft*8ft |

Moisture Content(%) | Fresh Veneers to within 12% |

Drying (℃) | 160-180℃ adjustable. |

Drying Capacity(M3/H) | 15-18m3/hour |

Veneer Speed(M/MIN) | 5-22m/min,16A Chain |

Power of Hot Air Fan (KW) | 2pcs×15KW×18section=540KW |

Power of Traction Motor(KW) | XWD6 Reducer Frequency Control |

Power of Cold Air Fan(KW) | 2pcs×15KW×3section=90KW |

Power of Dehumidifying Fan(KW) | 5.5KW×1pc=5.5KW |

Total Power | 680.5KW |