Automation Reaches New Heights in Veneer Drying

The wood processing industry is witnessing a transformative shift as automation technology fundamentally reshapes traditional production lines. At the heart of this evolution lies the wood veneer dryer, a critical piece of equipment whose operational paradigm is moving from labor-intensive supervision to largely unmanned, intelligent control. Modern, fully automated drying systems are now capable of continuous operation with minimal human intervention, requiring only operator monitoring of the system dashboard. This leap in automation, encompassing everything from automatic loading to finished product stacking, is setting new benchmarks for efficiency, consistency, and cost-effectiveness in veneer production.

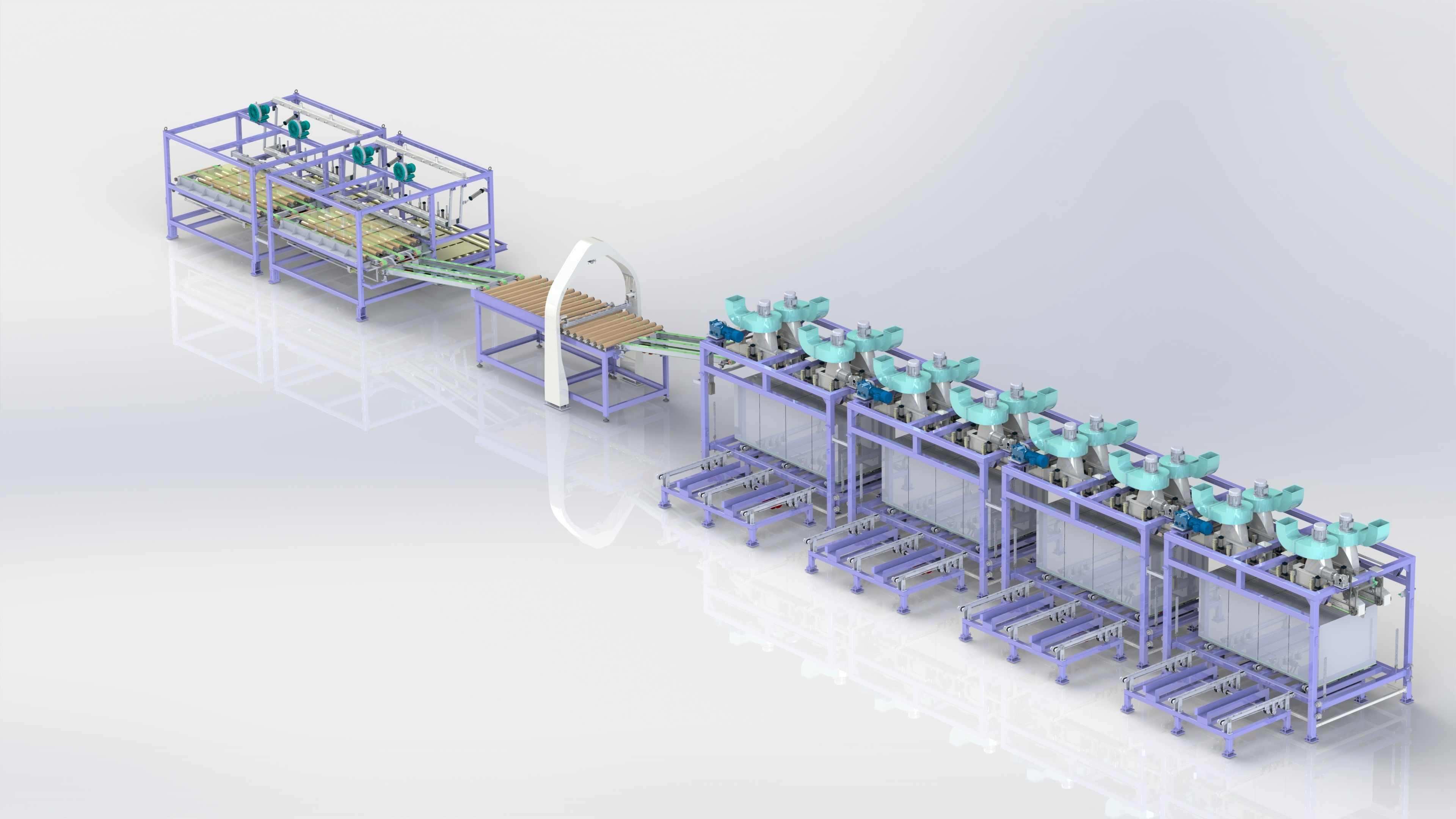

The journey towards a fully automated wood veneer dryer is built upon the seamless integration of several key subsystems, each performing a specific, critical function without manual assistance. The process begins with the Automatic Feeding System. This system utilizes robotic arms or conveyor belts equipped with precision sensors to gently and accurately place wet veneer sheets onto the dryer's intake. It eliminates the need for manual handling, which is not only time-consuming but also a common source of sheet damage and misalignment, ensuring a smooth and continuous flow of material into the dryer.

Once inside, the Automatic Variable Frequency Drive (VFD) Drying System takes over. This is the intelligent core of the dryer. Unlike older models with fixed settings, this system automatically adjusts temperature, fan speed, and conveyor belt velocity in real-time. It responds to pre-set parameters and feedback from sensors within the drying chamber, optimizing the drying curve for specific wood species and veneer thickness. This dynamic control prevents both under-drying and over-drying, guaranteeing uniform moisture content across every sheet while achieving significant energy savings.

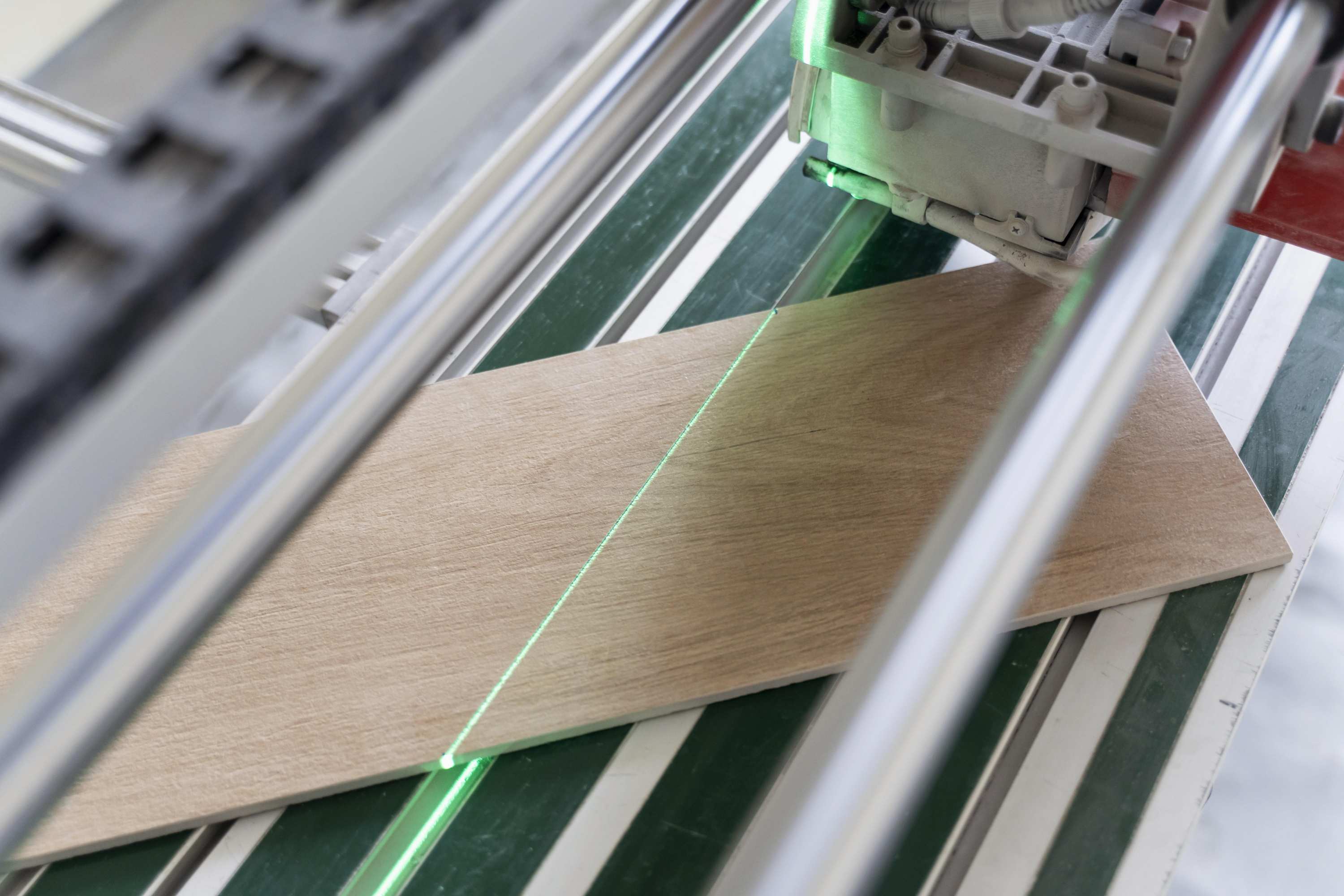

Concurrent with the drying process, the Moisture Content Detection System performs a critical quality control function. Using near-infrared (NIR) or radio-frequency (RF) sensors, it non-destructively scans each veneer sheet as it exits the main drying section. This system provides real-time, precise moisture data, allowing the dryer's logic to make final adjustments or automatically flag sheets that fall outside the acceptable moisture range (typically 6%-12%). This eliminates the delay and inaccuracy of manual spot-checking.

Following moisture detection, Visual Inspection Systems (also known as machine vision) offer an additional layer of quality assurance. High-resolution cameras capture detailed images of each sheet's surface. Advanced algorithms then analyze these images to identify defects such as cracks, knots, discoloration, or unacceptable grain patterns. Substandard veneer can be automatically flagged or diverted, ensuring that only veneer meeting the required grade proceeds down the line, thereby enhancing the overall quality and value of the final product batch.

The automation journey concludes with the Automatic Stacking and Palletizing System. Once dried, sorted, and inspected, the veneer sheets are conveyed to robotic arms that neatly stack them according to a pre-programmed pattern. These robots can handle heavy loads with precision, building uniform, stable stacks (or packets) that are then automatically strapped or wrapped for storage or shipment. This eliminates the heavy physical labor and potential for disorder associated with manual stacking, while also optimizing warehouse space.

Companies like Shine Machinery are at the forefront of integrating these technologies into reliable, production-ready solutions. The strength of a Shine Veneer Dryer lies not just in the individual components but in their sophisticated integration. The true measure of automation is how these subsystems communicate. In Shine's systems, data from the moisture detector feeds back to the VFD control system, creating a closed-loop process that continuously self-optimizes. This interconnectedness ensures that the entire line operates as a single, intelligent organism, maximizing throughput and minimizing waste.

The practical advantages of this high level of automation are compelling. Firstly, it delivers unmatched consistency and quality. By removing human variability from the process, every batch of veneer is dried to identical standards, which is paramount for downstream processes like lamination and pressing. Secondly, it drastically reduces labor costs and dependency. A single operator can monitor multiple dryer lines from a central control station, overseeing production rather than performing manual tasks. This also improves worker safety by removing them from high-temperature and heavy-lifting environments. Finally, the wealth of production data generated allows for precise OEE (Overall Equipment Effectiveness) tracking, predictive maintenance scheduling, and continuous process improvement.

In conclusion, the automation of the wood veneer dryer is no longer a future concept but a present-day reality that is redefining competitiveness in the wood panel industry. The transition from manual operation to a sensor-rich, self-regulating system represents a significant leap forward. For manufacturers, investing in such technology, as exemplified by the integrated solutions from Shine Machinery, is a strategic decision that directly translates to higher product quality, reduced operational costs, and a stronger position in the global market. The future of veneer drying is automated, data-driven, and remarkably efficient.