Daily Life of a Veneer Drying Machine Operator

Intro: We Know Drying Because We Live It

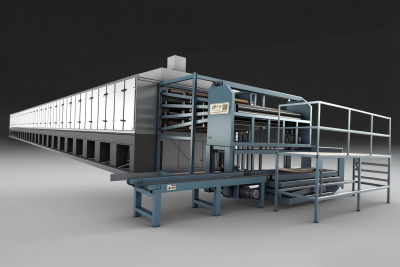

We’re Shine Machinery. We build drying equipment—but we also live inside the heat, sawdust, and motion of veneer production. We don’t just ship machines. We train veneer drying machinery operators. We listen to their stories. We tweak designs from real-world feedback.

This article? It’s not just tech specs and how-tos. It’s our inside scoop on what it takes to operate a veneer drying line like a pro—and keep those veneer sheets crisp clean and full of value.

Who Is a Veneer Drying Machinery Operator?

The operator? That’s the heartbeat of the drying process. This person is not just running a machine. They are the reason your plywood panels look sharp and last longer.

Eyes on Moisture Every Minute

Operators track moisture content non-stop. They make sure no wet veneer escapes undetected. Every sheet must hit the dried condition zone—no guesswork.

Manage Every Inch of the Veneer Drying Line

From loading raw veneer sheets to checking the outfeed temperature the operator controls it all. It’s a dance of timing pressure and precision.

Fine-Tune Drying for High Quality

Operators tweak airflow motor speed and heating zones to match the raw material. Poplar? Different from birch. Each species needs its own rhythm.

What Makes or Breaks Veneer Quality?

Even the best Veneer Dryer can’t fix a bad operator. Let’s break it down.

It’s All About Moisture

If you don’t dry it right

· Panels buckle

· Glue fails

· Plywood panels fall apart

Ideal moisture content? Around 6%–10%.

The operator hits this sweet spot every single run.

Don’t Burn the Sheet

Too much heat and the surface scorches. Too little and you get mold in storage.

Perfect drying feels like baking a pizza. You know it’s done by smell sound and feel.

Don’t Skip Safety

One wrong button and the entire veneer drying line shuts down.

A smart operator checks:

· Emergency switches

· Belt tension

· Fan rotation

· Fire-suppression sensors

What Happens Inside a Veneer Dryer?

Okay we promised not to say that term more than five times. So let’s call it "the oven" from now on.

Inside the oven your wet veneer goes through a transformation:

Heat and Motion in Sync

Veneer enters the preheating zone. Moisture starts to evaporate.

Then fans blast hot air through the conveyor zones. Operators adjust temperature as needed.

Drying Process by Stages

· Preheat stage: Softens fibers

· Drying zone: Removes 80% of water

· Cooling zone: Brings it to dried condition without cracking

Every second matters. Go too slow and your line backs up. Go too fast and your product fails.

We Smell the Finish

Veteran operators can literally smell good drying. Burned wood? Too late. Damp mustiness? Not done yet.

Yes seriously—ask any old-school operator.

Tools Every Veneer Operator Should Use

Let’s talk gear. An operator doesn’t show up with just gloves.

Daily Must-Haves

· Handheld moisture content meter

· Digital infrared thermometer

· Noise-canceling headset

· Clipboard with drying data logs

· Caliper for measuring veneer thickness

Optional but Awesome

· Thermal camera (find hot spots)

· Smartwatch with timer and alerts

· Remote monitoring tablet

Mistakes That Wreck Drying Results

We’ve all seen rookie moves. But they cost real money and real time.

Overloading the Feed Line

You get jammed veneer sheets and uneven airflow. Never force raw material down the chute too fast.

Ignoring the Alarm

That beep? It means a belt slipped or heat zones drifted. Operators must respond in seconds not minutes.

Skipping Daily Maintenance

Dust on fans ruins airflow balance. A $2 brush saves $2000 in repairs.

Tips from Real Operators Who Nailed It

Let’s hear from the folks on the ground floor.

Chen from Jiangsu

"I used to dry by instinct. Now I use data. Numbers never lie."

Maya from Vietnam

"I track drying times by wood species. Pine needs less heat than eucalyptus. That changed my output overnight."

Ahmed from Egypt

"I never trust just one reading. I check moisture content three times. Beginning middle and end."

These operators push the machine—but also push themselves.

What Makes an Operator Legendary?

Let’s be honest—not everyone’s cut out for this. But the best operators? They’ve got:

· Endurance (12-hour shifts on their feet)

· Sharp eyes (detect color changes fast)

· Quick reflexes (stop jams instantly)

· Tech savvy (understand temperature curves)

· Passion (they care about veneer quality)

And they love the sound of perfect airflow. Like a tuned engine—it just hums.

Final Thoughts: It’s More Than a Job

Here at Shine Machinery we respect the operator.

The person who keeps the veneer drying line alive. Who turns wet veneer into art. Who can sniff out a flaw before it happens.

No matter how advanced we build the oven—it’s only as good as the human running it.

If you’re a veneer drying machinery operator out there grinding every day—we see you. Keep that heat steady. Keep that line smooth. And take pride in every crisp clean sheet.

We’ll keep building better. You keep drying smarter.