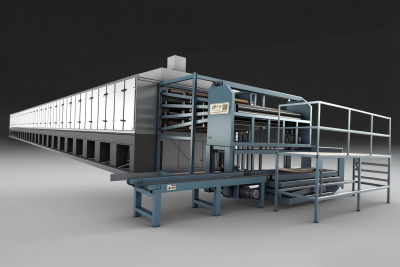

Ethiopian Veneer Project: Eight-Year-Old Veneer Dryer Still Work Out

Africa has long been celebrated as a paradise for timber resources, boasting a rich and diverse reserve of both softwood and hardwood that fuels the global wood veneer processing industry. In this thriving sector, veneer dryers have become indispensable equipment, and Shine roller veneer dryers, in particular, have gained a strong foothold, thriving amid the continent’s booming veneer demand. However, a unique story unfolded in Ethiopia, where one of Shine’s roller veneer dryers lay idle for five years before finally seeing the light of day— a journey marked by setbacks, resilience, and ultimate success.

The tale begins with a promising Ethiopian timber project that partnered with Shine to procure a state-of-the-art roller veneer dryer. Initially, the project held great potential, aligned perfectly with the global wood industry’s “golden period” of the past few years, when demand for high-quality timber products soared and market conditions were highly favorable. Everything seemed on track until a sudden and unexpected blow: the original investor abruptly withdrew funding midway through the project. This decision left the entire initiative in limbo, and Shine’s dryer, already shipped and partially installed, was left unused, unable to contribute to the project’s goals as the industry’s prime opportunity slipped away.

For 8 long years, the dryer sat dormant. Yet, hope was rekindled this year when a new investor stepped in, determined to revitalize the stalled project. As soon as Shine received the notification that the project was back on track, the company did not hesitate for a moment. Despite the passage of time and the challenges that came with it, Shine committed fully to getting the equipment up and running, driven by its dedication to client success and its reputation for reliability.

However, reviving the eight-year-old dryer was far from a straightforward task. In the intervening years, Shine had rolled out two major product upgrades for its roller veneer dryers. These upgrades were not just minor tweaks but significant enhancements, incorporating the latest technological advancements to improve energy efficiency, drying precision, and overall performance—keeping pace with the evolving needs of the global timber industry. As a result, the original dryer in Ethiopia now needed to be brought in line with these new standards. To make matters worse, over the five years of inactivity, some critical components of the dryer had been lost, and the original control programs, which were tailored to the initial version of the equipment, were no longer compatible with the upgraded systems. This meant the team had to start from scratch in many ways: remanufacturing missing parts with meticulous precision, redesigning components to match the upgraded specifications, and rewriting and testing control programs to ensure seamless integration with the updated hardware. Each step added layers of complexity, demanding time, expertise, and unwavering attention to detail.

Faced with these daunting challenges, Shine’s team rose to the occasion, embodying a spirit of unity and determination. From the company’s leadership, who provided strategic guidance and allocated the necessary resources to prioritize the project, to the technical design team, which worked tirelessly to adapt the upgraded technologies to the existing dryer, every department played a crucial role. The workshop staff responsible for manufacturing non-standard parts showcased exceptional craftsmanship, ensuring that each remanufactured component met Shine’s strict quality standards—standards that have defined the company’s reputation in the industry. Meanwhile, the on-site installation and commissioning team traveled to Ethiopia, ready to tackle the on-the-ground complexities. They worked long hours, navigating local logistical hurdles and carefully assembling, testing, and fine-tuning every part of the dryer.

What truly made the difference was the team’s collective focus: everyone, regardless of their role, was committed to the same goal—ensuring the dryer was commissioned on time. Meetings were held regularly to address bottlenecks, technical issues were solved through cross-departmental collaboration, and no effort was spared to overcome obstacles. Whether it was the design team adjusting blueprints late into the night, the workshop staff working overtime to finish a custom part, or the on-site team troubleshooting a last-minute glitch, every member of the Shine family pulled in the same direction.

Their hard work paid off. After weeks of intensive effort, the roller veneer dryer was finally completed and commissioned as scheduled. For the Ethiopian client, this marked the end of a five-year wait and the beginning of a new chapter—one where they can now tap into the timber industry’s potential and make up for lost time. For Shine Machinery, the project is more than just a successful equipment commissioning; it is a testament to the company’s core values: resilience in the face of adversity, dedication to client satisfaction, and the power of teamwork.