How to dry wood veneer?

Drying wood veneer isn’t just a step in production—it’s the heart of it. Get it wrong, and you're left with cracked sheets, warped edges, and high waste. Get it right though? You're staring at crisp, flat, high-quality veneer sheets that practically sell themselves.

We at Shine Machinery, as a leading Veneer Dryer Manufacturer, have spent years obsessing over this process. We’ve tested, tweaked, and torched more wood than we care to admit. This guide pulls from our firsthand experience—no fluff, just facts—on how to dry wood veneer the right way.

Let’s get into the nitty-gritty.

Why Drying Veneer Is a Make-or-Break Step

Drying is not just about getting rid of water—it’s about controlling moisture with sniper precision. Think of it like this: drying is where veneer becomes usable. Without it? You’re left with damp, unpredictable material that’s more likely to warp than wow.

Here’s why the drying process is critical:

· Wet veneer warps under pressure during pressing

· Uneven drying = cracks, blisters, and splits

· Over-dried sheets turn brittle and break like potato chips

· Under-dried veneer leads to mold, glue failure, and customer returns

The sweet spot? We aim for a moisture content between 6–12%, depending on species, usage, and storage plans.

Understanding the Veneer Drying Process

The drying of veneer involves heat, airflow, timing, and—most importantly—consistency.

Done right, it's fast, efficient, and gives you strong, stable veneer sheets ready for action.

Step 1: Measure Initial Moisture

Right after peeling or slicing, wet veneer can hold over 60% moisture. We don’t guess—we measure. High-accuracy moisture meters help us identify how much water we’re dealing with before it hits the veneer dryer.

Step 2: Set the Right Temperature and Humidity

Temperature and humidity must walk a tightrope.

· Too hot? You scorch the surface while locking in internal moisture.

· Too humid? The drying air can’t absorb any more moisture, leading to longer drying time and energy waste.

We’ve found our sweet spot between 140°C and 180°C, depending on the wood species. Meanwhile, we maintain 60–70% humidity inside the chamber for optimal evaporation rates.

Step 3: Control Drying Air Flow

You need airflow. Not a breeze. Not a tornado. A uniform, controlled drying air flow across all sheets is key to ensure no section dries too quickly or too slowly.

Our dryers feature high-precision fan systems that create even drying from edge to center.

Step 4: Nail the Drying Time

No two veneers dry alike. We adjust drying time based on species, thickness, and environmental conditions.

Going too fast? You’ll end up with warped junk. Too slow? You’re wasting electricity and production capacity.

Technology Behind Top-Tier Veneer Drying

Our drying technology has evolved with smarter systems that save time, money, and materials.

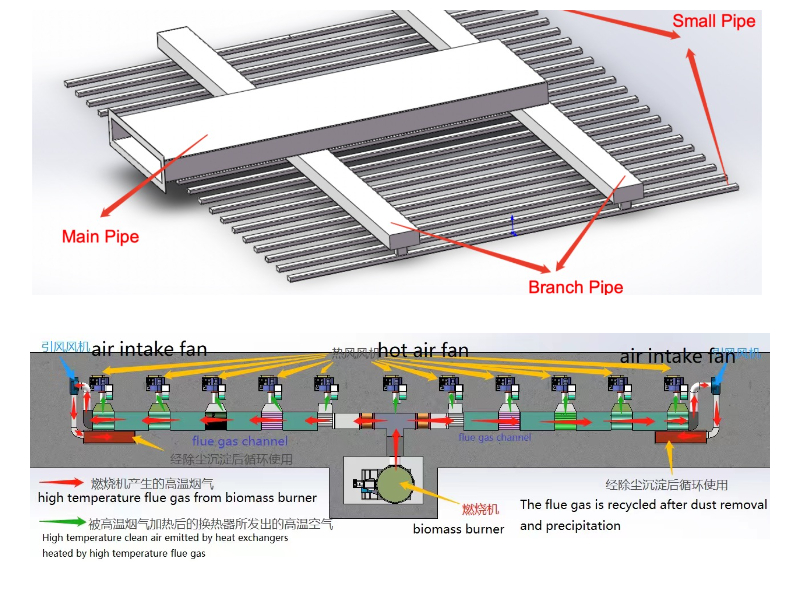

High-Efficiency Heat Exchangers

These units recover energy from exhaust air to preheat fresh air. Result? Up to 38% savings on energy consumption.

Real-Time Moisture Tracking

Smart sensors track veneer moisture during the process. The dryer adjusts automatically to prevent over-drying or under-drying.

Modular Dryer Design

Flexible design lets you expand your veneer production line without costly rebuilds. Ideal for growing operations.

Zone-Controlled Heating

Different zones in the dryer chamber adjust temperature independently. This ensures even veneer quality across the batch.

Common Drying Mistakes (And How to Avoid Them)

We've made these mistakes so you don't have to.

Drying all wood the same way

Solution: Know your species. Softwood dries quicker than hardwood. Customize settings.

Using outdated drying air systems

Solution: Upgrade to modern dryers with uniform airflow tech.

Overloading the dryer

Solution: Space your veneer sheets evenly. Crowded chambers = uneven drying.

Skipping moisture checks after drying

Solution: Use calibrated meters to verify every batch before stacking or pressing.

Ignoring the “wood memory” effect

Solution: Use post-conditioning (steam or rehydration) for sheets that need added flexibility before gluing.

How We Guarantee High Quality Veneer

Every step in our production process is designed to deliver high-quality results. Our team checks for:

· Surface flatness and consistency

· Color uniformity

· Absence of splits and cracks

· Correct moisture levels

· Bond strength in adhesive tests

We also run climate simulations to make sure the dry veneer holds up under real-world conditions.

The Eco Side: Saving Energy While Drying

Modern veneer production isn’t just about speed—it’s about responsibility. We’re proud to offer solutions that reduce energy consumption without cutting corners.

Here’s how we do it:

· Biomass-powered burners

· Pre-heating panels

· Automatic shutdown after cycles

· Thermal insulation around drying tunnels

· Energy feedback systems for reuse

Our goal? Produce better wood with a smaller footprint.

Pro Tips from Our Workshop Floor

We’ve been doing this a long time. Here are some golden nuggets:

· Use thinner sheets when possible—they dry faster

· Clean your dryers weekly to avoid airflow issues

· Watch for seasonal changes—wood reacts differently in winter vs summer

· Don’t store wet veneer too long before drying—mold grows fast

· Always monitor both input and output air temps

Unexpected Twist: Wood Has Mood Swings

Yes. Wood veneer—even once sliced—reacts to the environment. That’s why some veneer feels limp on humid days and crisp on others.

That’s why we sometimes steam-dress dry veneer before lamination. It revives flexibility for easier gluing and pressing. Bonus: it smells amazing.

We call it “spa day” for wood.

Final Words From the Drying Trenches

Drying wood veneer isn’t a glamorous job. But it’s the job that determines whether your product is premium or problematic.

We built Shine Machinery with one mission: help manufacturers get veneers that perform. With smart machines solid data and real experience—we deliver.

So if you're wondering how to dry wood veneer right, now you know. Control the temperature and humidity, manage your drying air, and don’t skimp on tech. Your veneer—and your clients—will thank you.

We’re not just drying wood. We’re building futures, one sheet at a time.