Maintenance Manual for Shine Roller Veneer Dryer

Basic Maintenance Principles & General Components

1. Preface

This manual is formulated to ensure the stable operation, extend service life, and reduce failure risks of Shandong Shine Machinery roller dryers. The maintenance of roller dryers follows the general characteristics of mechanical equipment maintenance, with special attention to the maintenance timing of high-temperature components and the use of high-temperature resistant lubricants. All operators and maintenance personnel must strictly abide by the regulations herein.

2. General Maintenance Characteristics

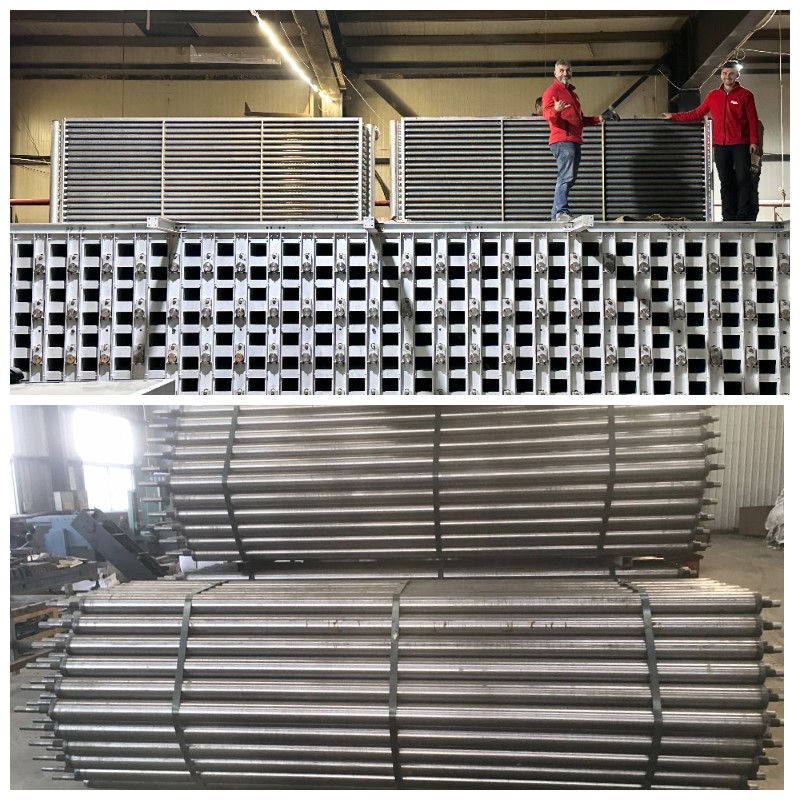

Veneer Drying Machine, as key equipment in material drying processes, consist of rotating rollers, transmission systems (reducers, gears, chains), bearings, motors, and high-temperature zones (e.g., heating chambers). Their maintenance shares commonalities with general mechanical equipment: regular inspection, lubrication, and parts replacement. However, due to the high-temperature working environment, special measures must be taken for components in contact with heat sources to prevent premature wear or failure caused by thermal aging.

3. Safety Precautions

- Prohibition of Lubrication During Operation: Under no circumstances should lubrication (oil or grease injection) be performed while the machine is running. Rotating parts (rollers, gears, chains) and high-temperature surfaces pose significant risks of entanglement, scalding, or mechanical injury. Always shut down the equipment, cut off the power supply, and wait for all moving parts to stop completely before conducting maintenance.

4. Maintenance of Transmission System

4.1 Reducer Maintenance:The reducer is critical for transmitting power and reducing speed, and its proper lubrication directly affects operational efficiency.

4.2 Lubricant Type: Use 220# gear oil. This viscosity grade is suitable for the load and speed of the reducer in Shandong Shine roller dryers, ensuring effective lubrication and wear reduction.

4.3 Oil Filling Quantity:

- For reducers with an oil level window, fill the oil to 2/3 of the window height. This prevents oil overflow during operation while ensuring sufficient lubrication of internal gears.

- For reducers without an oil level window, fill the oil to 1/3 of the gear height. Excessive oil will increase resistance and cause overheating, while insufficient oil will lead to poor lubrication.

5. Maintenance of Motor Bearings

Motor bearings support the rotating shaft and require regular lubrication to reduce friction.

- Maintenance Cycle: Generally, maintenance (grease replacement) should be performed every 1–2 years. The specific interval depends on the actual operating time and condition: if the motor runs continuously (e.g., 20 hours/day) or vibrates abnormally, shorten the cycle to 1 year; for intermittent operation (e.g., 8 hours/day), it can be extended to 2 years.

- Inspection Items: Check for abnormal noise, overheating (surface temperature exceeding 70°C), or grease leakage during operation. If any of these occur, stop the machine immediately for inspection and maintenance.