Vision Systems Transform Veneer Grading

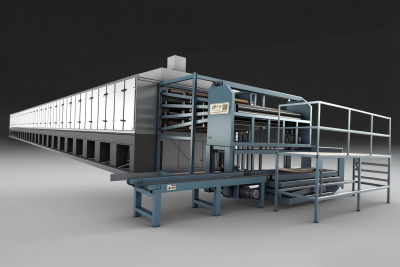

In the wood processing industry, grading veneer—thin wood sheets used in plywood, furniture, and decorative panels—has long been a bottleneck. Traditional manual inspection relies on human eyes to spot defects like cracks, knots, or color inconsistencies, but this method is slow, error-prone, and inconsistent. Enter vision inspection systems integrated with veneer dryers: a technological marriage that is revolutionizing how manufacturers ensure quality, boost efficiency, and adapt to modern production demands. This article explores how these systems work, their impact, and why they are becoming indispensable in the race toward Industry 4.0.

How Vision Systems and Veneer Dryers Collaborate: A Closed-Loop Workflow

The synergy between vision systems and veneer dryers hinges on a closed-loop quality control process—a cycle of “capture, analyze, decide, and feedback” that transforms raw veneer into graded products with minimal human intervention. Here’s a breakdown of the workflow:

1. Image Capture: Precision Imaging Post-Drying

After veneer exits the dryer, it moves along a conveyor belt into a dedicated inspection zone. Here, high-resolution industrial cameras (often paired with LED lighting to eliminate shadows) capture images from multiple angles. Advanced systems go beyond visible light: some integrate near-infrared (NIR) spectroscopy to measure moisture distribution (critical for preventing warping) and laser scanners to detect internal defects like voids or decay. For example, a 4K camera can resolve details as small as 0.1mm, ensuring even tiny cracks or insect holes are not missed.

2. AI-Powered Analysis: From Pixels to Classification

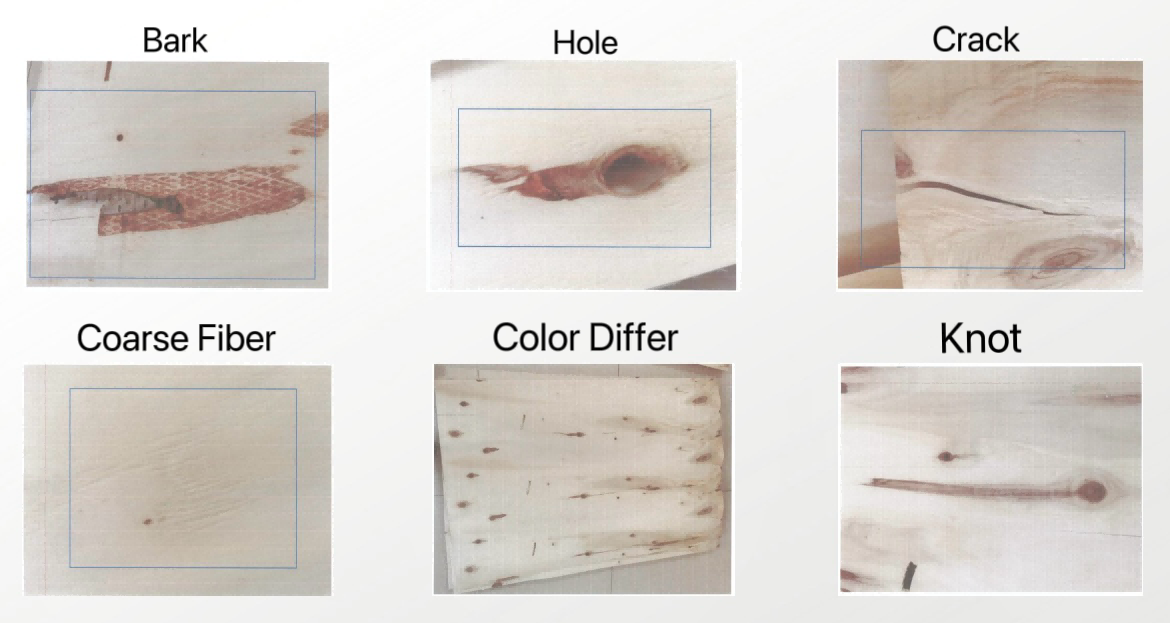

The captured images are transmitted to industrial computer running deep learning models, such as Convolutional Neural Networks (CNNs). These algorithms are trained on thousands of veneer images to recognize patterns:

Defect identification: Cracks (via edge detection algorithms like Canny), knots (distinguishing live knots from dead ones using texture analysis), and insect holes (morphological operations to count and size holes).

Geometric measurement: Calibrated cameras measure length, width, and thickness (tolerance ±0.1mm) and calculate warpage using 3D point cloud data.

Color/texture grading: HSV color space analysis detects (color variation), while Gabor filters assess texture uniformity to flag mold or stains.

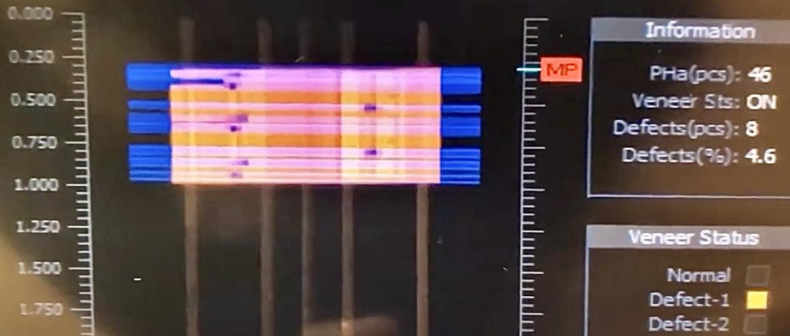

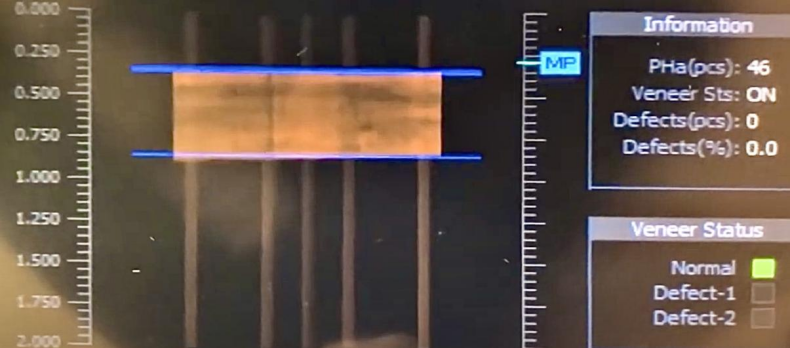

The system quantifies defects by area percentage (e.g., A-grade veneer allows ≤1% defect coverage) and density (e.g., ≤3 knots per square meter), aligning with industry standards like FSC certification or client-specific rules.

3. Decision-Making and Feedback

Once analyzed, the system assigns a grade (A/B/C or pass/fail) and triggers sorting mechanisms—pneumatic pushers, robotic arms, or diverter gates—to route veneer to designated bins. Simultaneously, data is fed back to the dryer’s PLC (Programmable Logic Controller) to adjust parameters (temperature, airflow) in real time. For instance, if moisture levels are uneven, the dryer might extend drying time in specific zones, preventing future defects.

Detection Methods: Multidimensional Precision

What sets modern vision systems apart is their ability to inspect veneer across multiple dimensions, ensuring no flaw goes undetected:

Surface Defect Detection

Cracks: Algorithms map crack length and depth, classifying them as “superficial” (repairable) or “critical” (reject).

Knots: Texture analysis differentiates live knots (blended with surrounding wood) from dead knots (dark, brittle), which weaken glue bonds in plywood.

Insect Damage: Morphological operations identify hole clusters, helping sort veneer for uses where aesthetics matter less (e.g., structural plywood).

Geometric and Dimensional Checks

Cameras measure veneer against strict tolerances: thickness (0.3–3mm for most applications), straightness (warping ≤2mm per meter), and edge squareness. This ensures compatibility with downstream machinery like laminators or CNC routers.

Color and Texture Grading

For decorative veneer (e.g., oak, walnut), systems use spectral imaging to match color tones across batches. A furniture maker, for example, might require consistent “golden oak” hues; the system rejects veneer outside the predefined range, maintaining brand consistency.

Core Benefits: Why Manufacturers Are Adopting Vision Systems

The integration of vision systems with veneer dryers delivers transformative advantages, addressing long-standing industry pain points:

1. Unmatched Accuracy and Consistency

Manual inspection averages 70–80% accuracy, with fatigue leading to missed defects. Vision systems boast 95%+ accuracy, as demonstrated by Shine Machinery’s clients: one plywood plant saw A-grade veneer yield jump from 75% to 92% after implementation. This consistency builds trust with buyers demanding defect-free products.

2. Cost Reduction and Labor Efficiency

A single vision system replaces 3–5 inspectors, cutting annual labor costs by 30,000–50,000 (based on Chinese factory data). It also reduces waste: by catching defects early, manufacturers avoid processing flawed veneer, saving raw materials and energy.

3. Data-Driven Process Optimization

Every veneer’s grade, defect type, and location is logged, generating reports that reveal trends (e.g., “knots increase in winter due to slower tree growth”). This data trains better AI models over time and guides dryer adjustments—for example, lowering temperature for sensitive species like eucalyptus.

4. Flexibility for Custom Orders

With modular software, systems quickly adapt to new grading standards (e.g., switching from A/B/C to premium/reject) or veneer types (thickness, species). A European factory producing custom furniture uses this flexibility to handle 10+ veneer varieties without retooling.

Real-World Impact: Case Studies

Two examples highlight the technology’s practical value:

European FSC-Certified Factory: The system automatically tags defects relevant to FSC audits (e.g., “sustainably sourced wood with minimal waste”), slashing audit preparation time by 50%. It also tracks defect origins, helping the factory improve forest management practices.

The Future: Smarter, More Integrated Systems

As Industry 4.0 advances, vision systems are evolving:

AI Model Refinement: Self-learning algorithms will adapt to new defect types without manual retraining.

Sensor Fusion: Combining vision with thermal imaging (to detect internal stress) or acoustic sensors (to listen for cracks during drying).

Cloud Connectivity: Data from multiple factories will be aggregated to train global models, benefiting smaller producers.

Conclusion

Vision inspection systems have transformed veneer grading from a subjective, labor-intensive task into a data-driven, automated process. By integrating with dryers, they create a closed loop that not only sorts veneer but also improves drying quality in real time. For wood processors, this means higher yields, lower costs, and the agility to meet diverse customer demands—all hallmarks of a competitive, sustainable operation. As the industry embraces smart manufacturing, vision systems will remain at the forefront, proving that precision and efficiency can coexist with nature’s raw beauty.