What temperature does veneer dry at?

Drying veneer is more art than science—though the science matters a lot. We've seen the disasters that happen when wet veneer doesn't get the right drying treatment.

Warped sheets, brittle edges, patchy color... yep, we’ve been there. But what is the right temperature? Well, let's get into it.

Why Veneer Drying Temperature Matters

The drying process is where veneer products go from meh to money. The wrong temperature leads to:

· Splits and cracks

· High moisture content

· Wasted energy

· Unusable veneer sheets

But the right drying temperature delivers magic—strong, smooth, high-quality veneer sheets that your customers love.

So... What Temperature Does Veneer Dry At?

Short answer: 60°C to 180°C (140°F to 356°F)

Long answer? It depends on the:

· Wood species (Birch dries different from Poplar)

· Moisture content of the wet veneer

· Drying method used (Hot air? Steam? Infrared?)

· Thickness of the veneer sheets

Here’s a breakdown:

Wood Type | Drying Temp (°C) | Drying Time (min) |

Poplar | 65–90 | 10–15 |

Birch | 80–120 | 12–18 |

Beech | 100–150 | 8–12 |

Oak | 130–180 | 5–8 |

👉 Rule of thumb: Higher density = higher drying temperature.

Factors That Affect Drying Results

We don’t just crank up the heat and pray. There are key parameters we always check:

1. Initial Moisture Content

Too wet? You need to start low. Veneer that starts at over 80% moisture will bubble, blister, or curl at high temperatures.

2. Dry Veneer Final Target

Ideal moisture content? About 8–12% for most veneer products.

3. Drying Uniformity

Uneven heat leads to uneven veneer. Simple as that. You get bright spots, dark spots, or worse—cracks.

4. Energy Consumption

High temperatures eat energy. We balance between optimal drying and keeping power bills low.

What We’ve Learned From Years in the Game

We’ve dried millions of square meters of veneer sheets. Some batches made us cheer. Others? Not so much. Here’s what experience taught us:

💡 Start Low, Finish High

We preheat at lower temperatures to slowly remove bound water. Then we ramp up to finish the job fast.

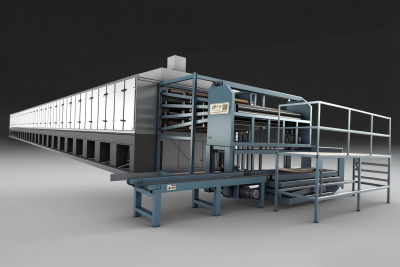

💡 Use Zoned Drying

A good Veneer Drying Machine uses multiple zones. Each zone has its own temperature control. That keeps the veneer drying process efficient and effective.

💡 Speed + Heat = Danger

Going too fast at high temperatures? That's how you turn beautiful veneer into firewood.

Our Drying Process for Top-Quality Results

We follow a step-by-step system that guarantees high-quality drying results:

1. Moisture Scan – We measure every wet veneer batch

2. Load It Evenly – No overlapping veneer sheets

3. Start with Preheat Zone – Around 60°C

4. Move to Main Zone – Gradually up to 120–160°C

5. Final Zone – Lower temp finish to set the moisture level

6. Unload & Stack – With air circulation to balance out internal moisture

This system reduces energy consumption while improving product quality. Win-win.

Energy Efficiency Is Our Secret Weapon

Let’s be real. Energy prices aren’t going down. We designed our machines to keep heat inside and use it wisely.

Here's how:

· Insulated chambers

· Automatic temperature control

· Recirculated hot air

· High-efficiency fans

End result? We cut energy consumption by 15–30%, and our customers notice the savings.

Tips for Drying Veneer Like a Pro

Want to dry veneer without headaches? Follow these:

✅ Don’t overload the machine

✅ Keep the veneer thickness uniform

✅ Clean out dust regularly

✅ Check exhaust temperature daily

✅ Rotate drying zones every 4 hours

Also—don’t forget humor! A happy operator makes fewer mistakes. Seriously.

Common Mistakes to Avoid

🚫 Cranking the temperature to max from the start

🚫 Ignoring moisture levels

🚫 Using the same setting for all wood species

🚫 Not maintaining your Veneer Drying Machine

Our first week in the factory? We made all of these. Learn from us—don’t repeat history.

Why Our Customers Trust Our Veneer Drying System

We didn’t just build a machine. We built trust. Customers say our machines:

⭐ Dry veneer fast but gently

⭐ Deliver consistent quality

⭐ Use less energy

⭐ Need less maintenance

We build each system with care because we know how important each veneer sheet is.

Final Thoughts: Find Your Sweet Spot

Drying veneer is all about balance. You’re juggling temperature, time, wood species, and moisture. Get it right, and you’ve got a product worth showing off. Get it wrong, and your veneer sheets are firestarter material.

We’ll help you find your sweet spot. That’s why we do what we do.