What is a veneer dryer?

If you've ever touched a smooth sheet of plywood and wondered how it became so crisp and flat—welcome to the secret world of veneer drying.

At Shine Machinery, we live and breathe veneer. Our passion? Helping people like you understand how vital a Veneer Drying Machine really is in producing high quality veneer. Let’s peel back the layers and show you how the drying process transforms soggy sheets into ready-to-glue champions.

Why Wet Veneer Needs Drying (Fast)

Before veneer becomes part of furniture or construction panels, it comes off the log wet—very wet. That wet veneer contains 50–80% moisture. If we skip drying, bad things happen: warping, fungal growth, delamination. Ugly stuff.

That’s where the veneer drying machine steps in. Its job? Reduce moisture content to 8–12% without damaging the sheet. Sounds simple. It’s not.

We’re working with hot and humid air, delicate fiber, and tight tolerances. Drying veneer sheets is a science and an art.

The Veneer Drying Process: Start to Finish

Let’s break this down step-by-step.

1. Moisture Check-In

· Each batch begins with a moisture content scan

· Boards above target moisture go straight to the dryer operation queue

2. Hot Air, Meet Wet Sheet

· Inside the veneer drying machine, we control temperature and humidity

· Drying air flows across the sheets, removing water like a vacuum

· Depending on the wood species and thickness, the drying speed changes

3. The Flip and Flow

· Our system flips the veneer to dry both sides evenly

· Uneven drying = cupping = ruined veneer products

4. Out Comes Perfection

· Sheets exit the dryer flat, stable, and ready to be glued

· We aim for optimal drying without splits or darkening

Drying too fast? You get cracks. Too slow? Energy costs skyrocket. It’s all about precision.

How We Get High Drying Capacity With Low Energy Use

Energy costs matter. That’s why we design for energy efficiency without sacrificing results.

What We Do Differently:

· Smart air recirculation to trap heat and reduce fuel usage

· Auto-adjust temperature and humidity for each batch

· Insulated chambers = no heat escapes

· Moisture sensors guide the speed and airflow in real time

This tech reduces energy consumption by up to 30% compared to older systems.

Good Drying = Good Business

Here’s what optimized veneer drying means for your factory:

· ✅ Fewer rejected sheets

· ✅ Higher yield from the same logs

· ✅ Better bonding during gluing

· ✅ Smoother surfaces for coating or laminating

We’ve seen clients double their production quality just by upgrading their dryers.

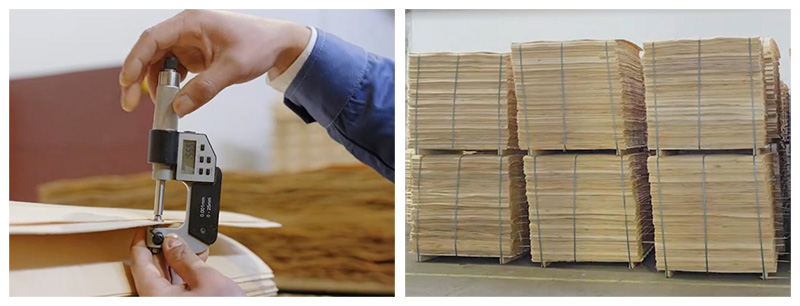

What Makes a Drying Result “High Quality”?

It’s not just about reaching target moisture. It’s about consistency across the whole sheet and batch.

Look For These:

· Uniform color

· No burn marks or dark spots

· Zero warping or edge curling

· Moisture content within ±2% across the sheet

Anything less? That veneer may not bond properly or may crack during pressing.

Real Talk: Why Drying Veneer Isn’t Optional

We’ve met folks who tried skipping veneer drying. Spoiler: it never ends well.

Here’s what you risk:

· Adhesive failure = peeling layers

· Swelling in final panels

· Mold growth in storage

· Lower resale value

Think of drying as seasoning food. Skip it, and everything tastes wrong.

Tips From Our Team: How To Optimize Dryer Operation

We’ve helped dozens of factories fine-tune their dryer operation. Here's what works:

1. Pre-sort veneer by thickness

2. Keep logs fresh to reduce drying time

3. Don’t overload the dryer—airflow needs space

4. Calibrate your moisture sensors weekly

5. Watch for airflow blockages (dust is sneaky)

And most importantly—listen to your dryer. It talks through output quality.

A Twist You Didn't Expect: Veneer Smells Better When Properly Dried

Okay, it's a little weird—but true! Properly dried veneer smells woody, not sour. That’s a bonus when customers open a shipment.

Final Thoughts From Our Shop Floor

We know this industry. We’ve been designing veneer drying machines for decades, and we still get excited every time a new model gets fired up.

There’s something satisfying about seeing wet sheets go in and perfect ones come out. Dry veneer sheets are more than a product—they're a promise of quality.

We’re not just here to sell machines. We’re here to help you get the best drying results with the lowest energy use, highest uptime, and zero guesswork.

Got questions? We’ve got answers. Let’s dry something great together.

🔧 Quick Recap in List Form

· Veneer drying is essential before gluing

· Moisture should be reduced to 8–12%

· Temperature and humidity must be carefully controlled

· Airflow and flipping = even drying

· Energy efficiency boosts profits

· Proper drying improves bonding and quality

· Every veneer sheet deserves attention

· We help you get it right—every time