How to Choose the Right Veneer Drying Machine?

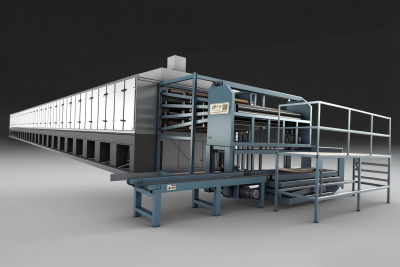

Selecting the perfect veneer drying machine is a critical decision for wood processing businesses, directly impacting production efficiency, product quality, and long-term profitability. With numerous options available in the market, navigating the choices requires a strategic approach that balances production needs, equipment performance, energy costs, and budget constraints. At Shine Machinery, we specialize in tailoring solutions to empower manufacturers with the ideal roller veneer dryer for their unique requirements—here’s our expert guide to making an informed choice.

1. Start with Your Production Needs: Size, Volume, and Flexibility

The first step in choosing a veneer drying machine is to evaluate your production scale and material specifics. Key considerations include:

Daily Output Requirements: Do you need a machine that processes 30 cubic meters of wood veneer sheets per day, or do you require a high-capacity model capable of 300 cubic meters? Shine Machinery’s roller veneer dryers are fully customizable, with production capacities spanning this entire range to match small workshops, medium-scale factories, or large industrial lines.

Veneer Dimensions: From narrow strips (e.g., for furniture edges) to wide planks (e.g., for construction panels), our dryers accommodate varying veneer widths—ensuring no material is wasted and every sheet meets your specifications.

Factory Space: Limited floor space? Our compact yet powerful designs optimize layout efficiency without compromising output, making them ideal for facilities with tight constraints.

2. Prioritize Performance Parameters: Temperature Control and Drying Speed

A veneer drying machine’s ability to maintain consistent temperature and adjust drying speed is pivotal to avoiding defects like warping, cracking, or uneven moisture content. Shine Machinery’s solutions stand out with:

Variable Frequency Control System: This advanced technology dynamically adjusts the dryer’s operating parameters (e.g., conveyor speed, heater output) based on the wood species and veneer thickness. Whether you’re drying thin birch veneers or thick rubberwood sheets, the system ensures optimal drying conditions—no manual guesswork required.

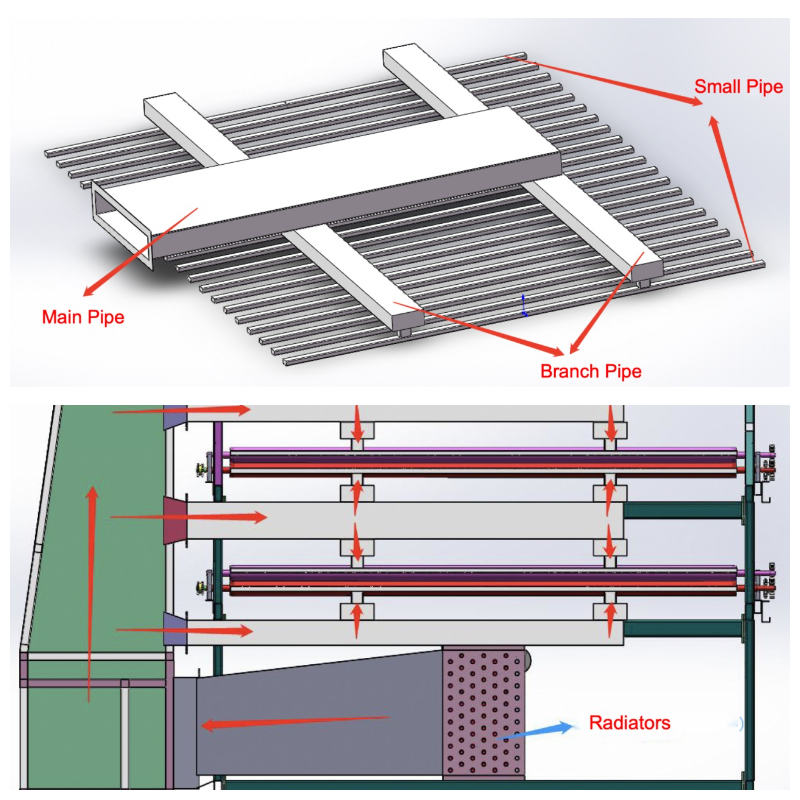

Uniform Heat Distribution: Our proprietary heat exchange system distributes warm air evenly across every veneer sheet. This eliminates “hot spots” or under-dried areas, guaranteeing flat, high-quality veneers with consistent moisture levels (8–12%—the industry standard for premium applications).

3. Evaluate Energy Efficiency: Lower Long-Term Costs

Energy consumption is a major hidden cost in veneer drying. Shine Machinery addresses this with two key innovations:

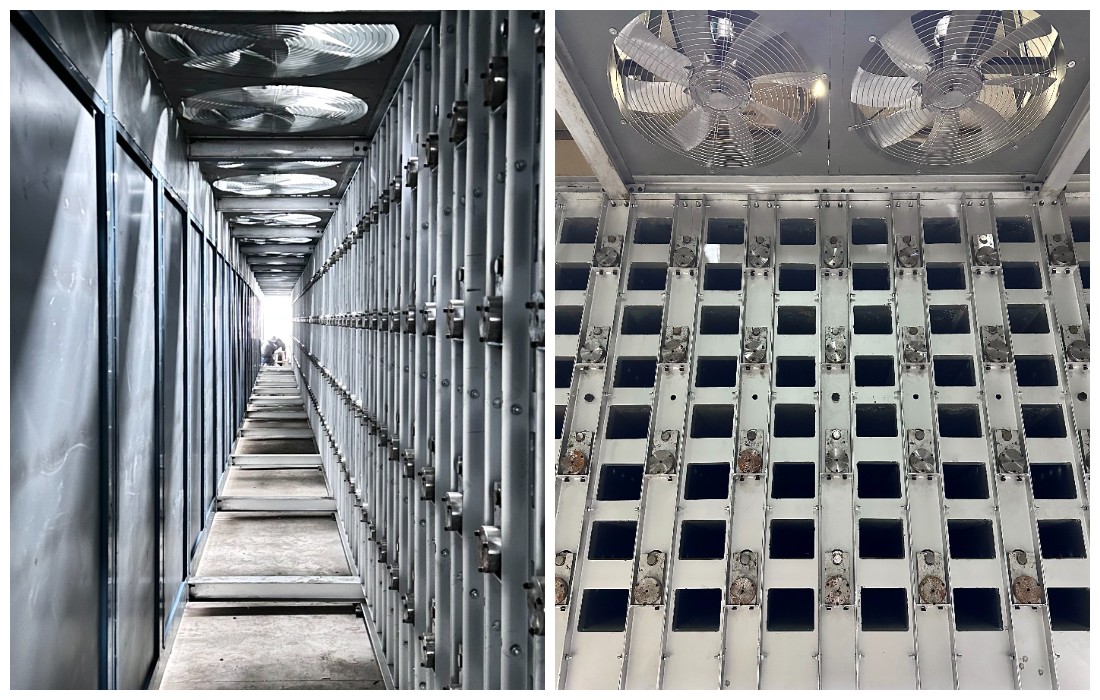

Latest Axial Flow Fans: Replacing traditional fans, these high-efficiency models deliver the required airflow for drying while reducing total power consumption. This translates to lower electricity bills and reduced environmental impact—critical for businesses aiming to meet sustainability goals.

Smart Energy Management: By integrating with renewable energy sources (e.g., biomass burners, as featured in our previous models) or optimizing grid power use, our dryers minimize reliance on expensive fossil fuels, further lowering operational costs over time.

4. Budget Wisely: Balance Upfront Costs with Total Value

While upfront costs are important, focusing solely on price can lead to long-term regrets. Shine Machinery advocates for a “total cost of ownership” approach:

Customized Solutions: A one-size-fits-all dryer may seem cheaper initially but could incur higher maintenance, energy, or waste costs over time. Our tailored designs eliminate these risks by aligning with your exact needs—from heat source selection (biomass, thermal oil, etc.) to conveyor belt configurations.

Durability and Support: We use premium materials (e.g., high-temperature-resistant alloys for heat exchangers) and offer comprehensive after-sales service, ensuring your dryer operates reliably for years. This reduces downtime and repair costs, maximizing your return on investment.

Why Choose Shine Machinery as Your Preferred Drying Facility ?

At Shine Machinery, we don’t just sell veneer drying machines—we deliver tailored solutions that grow with your business. Our roller veneer dryers combine cutting-edge technology (variable frequency control, axial flow fans, uniform heat exchange) with unmatched customization, ensuring you get a machine that:

Meets your daily output goals (30–300 m³/day).

Handles diverse wood species and veneer thicknesses.

Minimizes energy costs through smart design.

Delivers consistent, defect-free veneers for premium applications.

Choosing the right veneer drying machine is about more than just specifications—it’s about aligning equipment with your production reality. With Shine Machinery’s custom-engineered roller veneer dryers, you gain a partner that prioritizes efficiency, quality, and long-term value. Ready to transform your veneer production? Contact us today to discuss your needs and discover how our solutions can elevate your business.

Shine Machinery: Drying Excellence, Tailored to You.